| Author | Message | ||

| Tim Hogan (Tojo)

Junior Member Username: Tojo Post Number: 108 Registered: 4-2002 |

Hey Pete, I got my pax side going fine. I still have to do my drivers door. It's a prick of a job first time but once you know what you're doing it's ok. The red and white supermarket supllied all my needs. I'll be happy to give you a hand. | ||

| Peter B. (Gts308qv)

Member Username: Gts308qv Post Number: 251 Registered: 5-2001 |

Well Tim ! Once you have fixed your windows, you will have to come over and help me correct a sticking drivers side window on my QV. Getting tired of needing a second person to pull up on the window to wind it closed. Beers are on ice, ready to go! | ||

| Tim Hogan (Tojo)

Junior Member Username: Tojo Post Number: 106 Registered: 4-2002 |

Hi guys, this is fantastic stuff and will save me hours of greif and cursing. Thanks heaps | ||

| Phil Hughes (Ferrarifixer)

Junior Member Username: Ferrarifixer Post Number: 89 Registered: 7-2003 |

Excellent post gianluca. On new motor/cable units there is a plastic clamp device for holding all the windings in the correct position while you fit it all in. I have one of these which I've added a length of cable to, in order to be able to get it out very easily when you're done. It makes the job very easy as you say. I've done the whole thing from start to finish in about 2 hours a couple of times, but more like 4 hours is the norm by the time you clean the old hard/sticky grease out and re-pack it. | ||

| Gianluca Chegai (Gianluca)

New member Username: Gianluca Post Number: 21 Registered: 5-2003 |

Tim, I just finished doing my 308 windows. For the passenger door I used Verell's excellent post (I do not have it handy but can look for it) with some slight modifications. It was a PITA but it worked fine. The hardest part was to clean the gear system with the cables still tied to the car, crouched by the door. When I did the passenger door, however, the cables had been previously removed and they were all messed up: kinked, twisted etc. Under these circumstances there was NO way to put them together again. Everything MUST go back exactly right or it will not work. I spent hours trying and no luck. My procedure now is as follow. By the way this makes the job very easy and with the best possible results. Go to Sears Hardware and buy 12 feet (10-11 ft. I believe is all you need)of 1/16" stainless steel cable and a pack of 1/16" cable stop (comes in packages of 5 or 6 and is simply a small aluminium "tube" about 1/8" thick, 1/4" dia. or so with a 1/16" hole). Take the WHOLE assembly out of the door (yes, undo the window nuts that hold the glass to the cable. On the bench, you can take the gear motor apart and you will see how the cable is inserted and you can replace it. This is very easy and if you are tackling the windows job, you will not have any problems at all. There was a trick about removing the shaft that holds the convex metal disk but I do not remember what it was, but nothing special once you study it. I just remeber that it took me a few extra minutes (I believe it was a difficult retaining ring). Sorry I do not remember. Now, you MUST use a special swaging tool ( Swage-IT # 2 )to do the new cable stops and Sears Hardware has it next to the cable and ferrules. It may be kind of expensive (25-35 $)but it is worth it. I also used it to make a new parking cable: perfect. When you have everything re-assembled (everything cleaned, new cable) the correct amount of turns of the cable is: every groove must be used, no more, no less. The cable will want to lay in the spool going opposite directions. If you get an overlap = too many turns; if you see a whole groove free = too few turns. It will come down to 5 turns (if memory serves me well). From the parts drawing you will see how the cable is supposed to run on the pulleys. I had my wife read it to me as I was doing it: took maybe 1 minute! Also, as you re-assemble the gear motor, do notice the exit point of the cable around the 3 studs. If you consider the edge were the little shaft that goes on the electric motor to be the base of an isosceles (?) (translating from Italian) triangle, you have, then, the opposite stud which would be the vertix of such triangle. The cables will have to exit one from one side of the vertix and the other from the other side of the vertix (following the natural lay of the cable). This is shown on the parts manual. Believe me that that puppy will go back in at the first try, 1-2 minutes max! You will understand, as you will handle the new cable, that there is no more need to "fight the cable itself because is nice and LIMP. No kinks, no distorsion, no memory from being wrapped around a spool for 20+ years and no STIFFNESS. I actually think that doing a window job is now easy, fast and fun. If I will need to redo it in the future, I will buy new cable and be done with it. That is all the difference in the world. The way I re-attached the windows, was to spool all the way up with the console button, back up just a tad, and holding the window up (can use soft clamps or ask a helper) re-clamped the new cables in place. It may be tricky to get to both nuts in this position but you can mark the cable and lower it (with the window) to a more comfortable position. Old cable .070 New cable .064 Negligeable difference. Cable stops will fit with NO modifications. Total cost $ 5-6 plus tool (which could be returned after you use it but I believe you will want to keep it as it will do also the parking brake job and who knows how many more cable in the car) Tim, sorry for the long post and for lack of very specific, step-by-step instructions. The "spirit" of the post is, however, to buy the new cable AND to take the whole thing out. As I said before, you will not need any more instructions than these. You will be able to do it first time around. Best of luck, Gianluca | ||

| Randy Rosser (Randy_308)

New member Username: Randy_308 Post Number: 2 Registered: 8-2003 |

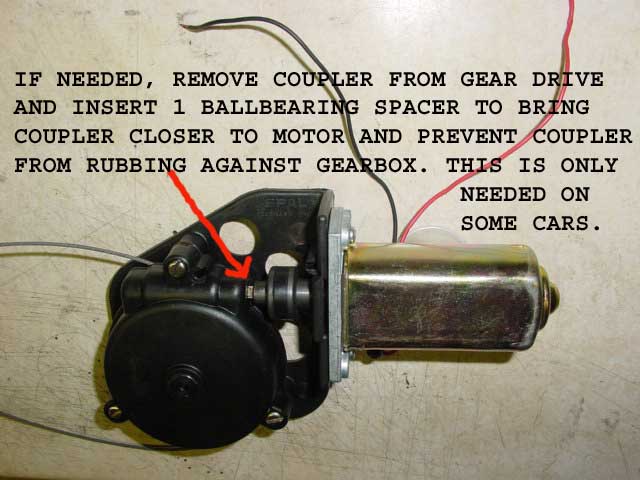

Tim, I hope these pictures attach and they will be of some help to you. I went through the same thing and ended up by passing the circut board and wiring the motors through relays and breakers. My windows now work like a new car. If you need part numbers let me know. Regards, Randy             | ||

| Randall (Randall)

Member Username: Randall Post Number: 628 Registered: 1-2003 |

Did you count the number of times that the cable was wound on the spool? Make sure you have it the correct number. Also make sure you have the cable crossed the right way, otherwise it will bind when you try to raise/lower the window. | ||

| Tim Hogan (Tojo)

Junior Member Username: Tojo Post Number: 105 Registered: 4-2002 |

I've pulled apart my 308 window motor cable and motor thing to lube everthing up and make things go better. I didn't think they could get any worse. But now with all the cables loose and all over the place I 'm looking for tips on winding the cable back around the pulley and making things work again. There is copious amounts of appreciation to anyone who can help me out |