| Author | Message | ||

| Yoshi Toda (Ytoda928)

Junior Member Username: Ytoda928 Post Number: 80 Registered: 6-2001 |

Ron Davis' has just quoted me $950.00!!! I think that is way too much. | ||

| Mark Eberhardt (Me_k)

Member Username: Me_k Post Number: 784 Registered: 5-2002 |

Bill, Mine is a griffin. Since I want a well oversize unit that I know won't never "bolt-in", I just took the $180 off the self unit form Summit racing and made it fit instead of custom at $600. | ||

| Bill V (Doc)

Member Username: Doc Post Number: 451 Registered: 9-2001 |

Mark--where did you get your radiator again? | ||

| Bill Sebestyen (Bill308)

Member Username: Bill308 Post Number: 551 Registered: 5-2001 |

I made a mistake in the word equation solving the heat transfer resistance equation provided in my post, so I correct it below. R-convection coolant to tube + R-conductivity from tube id to middle of fin + 1/((1/R-convection to air) + (1/R-radiation surroundings)) = equals the total heat transfer resistance. Again, a lower heat transfer resistance is better. Convection to the air stream and radiation to the surroundings are parallel heat transfer paths. | ||

| Mark Eberhardt (Me_k)

Member Username: Me_k Post Number: 768 Registered: 5-2002 |

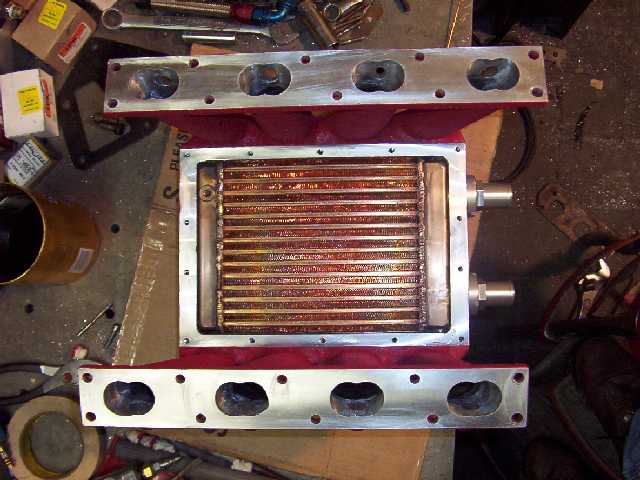

Here's some more info. In most places, including radiators, copper corrodes much slower than aluminum, but I have never seen a copper auto radiator, brass is the old standard and also has good corrosion resistance, but does not have the conductivity. The fins are soldered to the tubes and the solder is a terrible conductor so the heat doesn�t get to the fins very well. Also, for weight reasons, the tubes can only be made � - 5/8 wide where aluminum tubes can be made 1.5� wide which increases the effective surface area. Over all, an aluminum radiator of equal dimensions to a brass radiator will cool about 20% better. A true copper radiator would weight a ton, but be 100% better than the aluminum. The intercooler I just put on my 308 has a copper core with the fins welded to the core tubes, it measures 10� x 7� x 2.125� and cost $1500�.the aluminum radiator I have is something like 22� x 18� x 2.5� weights less and cost $180 for what it�s worth (oh, and all the cooling problems are gone).   | ||

| Yoshi Toda (Ytoda928)

Junior Member Username: Ytoda928 Post Number: 79 Registered: 6-2001 |

This is the exact topic I have been looking for. The radiator for my 85 308QV (US Spec) is going bad and needs to be replaced. I always wanted to know more about the aluminum radiator as the replacement. I would like to contact Ron as it seems to be the right choice. But, I do no have any drawing or part number to reference. Do you think he can make one without having my car on-site because I live in northern California. Can anyone help? Thanks in advance, Thanks! Yoshi | ||

| Bill Sebestyen (Bill308)

Member Username: Bill308 Post Number: 550 Registered: 5-2001 |

There are four heat transfer processes taking place in a radiator. The first process is transfer of the coolant heat to the inside surface of the tubes. This is a convection process where the tube material doesn't matter. The flow rate, id, and tube surface area do matter. Corrosion buildup acts as an insulator and degrades a heat exchanger's efficiency. The second process is conduction of the heat from the inner wall of the tubes to the fins. Higher fin temperature is better. A higher conductivity material will result in a higher temperature at the tip of the fins, that area farthest away from the tubes. Here, high conductivity matters. Copper is better than aluminum by a factor of 2-3. The third process is convection to the air-flow through the fin matrix. For this process, the radiator material is unimportant but the aspect ratio (ratio of the distance between tubes and the width of the fins perpendicular to the air-flow) is important. If the distance between the leading edge of the fin and the trailing edge of the fin is large, the fin will be less efficient, even though the surface area will be greater. The end result will be an increase heat transfer, do to increased convection area, but a decrease in efficiency due to air-boundary layer buildup. The fourth process is radiation where heat is rejected to the surrounding area. Since the fins generally are "looking at each other", only the upper and lower tank skins benefit from this process. Radiation is proportional to the difference between the surrounding temperature and the header temperature to the 4th power of their absolute temperatures. Since the effective surface areas involved are small and the temperature differences are relatively small (110 C � 25 C), the radiation contribution is small. Lower is better. A proper analysis would sum the all resistance contributions as follows: R-convection coolant to tube + R-conductivity from tube id to middle of fin + 1/(R-convection to air + R-radiation surroundings) = equals the total heat transfer resistance. Again, lower is better. Radiator material conductivity only plays a part in the process. Corrosion on the id of the tubes, over time, is important as is fin geometry. I hope I've put the physical relationships in prospective here. It's not an easy call when one runs the numbers on a hyopothetical case. The devil is in the details. By the way, they actually pay me to do these kind of analyses. I hope this helps. | ||

| Bill Sebestyen (Bill308)

Member Username: Bill308 Post Number: 549 Registered: 5-2001 |

There are four heat transfer processes taking place in a radiator. The first process is transfer of the coolant heat to the inside surface of the tubes. This is a convection process where the tube material doesn't matter. The flow rate, id, and tube surface area do matter. Corrosion buildup acts as an insulator and degrades a heat exchanger's efficiency. The second process is conduction of the heat from the inner wall of the tubes to the fins. Higher fin temperature is better. A higher conductivity material will result in a higher temperature at the tip of the fins, that area farthest away from the tubes. Here, high conductivity matters. Copper is better than aluminum by a factor of 2-3. The third process is convection to the air-flow through the fin matrix. For this process, the radiator material is unimportant but the aspect ratio (ratio of the distance between tubes and the width of the fins perpendicular to the air-flow) is important. If the distance between the leading edge of the fin and the trailing edge of the fin is large, the fin will be less efficient, even though the surface area will be greater. The end result will be an increase heat transfer, do to increased convection area, but a decrease in efficiency due to air-boundary layer buildup. The fourth process is radiation where heat is rejected to the surrounding area. Since the fins generally are "looking at each other", only the upper and lower tank skins benefit from this process. Radiation is proportional to the difference between the surrounding temperature and the header temperature to the 4th power of their absolute temperatures. Since the effective surface areas involved are small and the temperature differences are relatively small (25 C � 110 C), the radiation contribution is small. A proper analysis would sum the all resistance contributions as follows: R-convection coolant to tube + R-conductivity from tube id to middle of fin + 1/(R-convection to air + R-radiation surroundings) = equals the total heat transfer resistance. Radiator material conductivity only plays a part in the process. Corrosion on the id of the tubes, over time, is important as is fin geometry. | ||

| Julio Valladares (Jbanzai)

Junior Member Username: Jbanzai Post Number: 106 Registered: 2-2002 |

I am amazed how much knowledge there is in this forum, thanks guys  I am learning a lot. I am learning a lot. Dave, Madrid is a very intereresting place in many many aspects, and weather wise too. We have from incredible hot summers to very cold winters, with a little snow in January, and nice soft temperatures in spring and fall, 3 months of everything with an average of 260 clear sky days a year, and always low humidity, I like it. This summer, however, was the hotest summer in the last 2 centuries, and some people still dennys the Global Warming. In a normal year, summer temperatures top at a 100F, but this year we reached 125F for about a week, it was unbearable. Streets were desertic from 2PM till 8PM every day, I have never seen a 6 million people city so empty in all the years I lived here. And it did stay over 100F for more than a month. I think I am going to try a double pass Aluminum radiator built by Ron Davis, he seems to have a good reputation over there. My other option is to re-core the actual one and improve it, but that shops I found here in Spain does not isnpire me much confidence, as none of them really wants to do it. So to do a good job I will have to ship my radiator overseas, and leave my car undrivable for prrobably a month, and I will end with similar costs to the new Aluminum one anayways. Thanks guys, you really helped me to take a decission, I will let you know the results when I get it and I install it. Julio | ||

| Bill Sebestyen (Bill308)

Member Username: Bill308 Post Number: 547 Registered: 5-2001 |

Julio, If copper corrodes faster than aluminum, and I don't know if this is the case, thicker material will give a longer life. From a conductivity point of view, thicker is better. But this is not the only issue in optimizing a radiator. Shape and surface area of both the tubes and the fins are equally important. For a properly designed radiator having equal efficiencies, the aluminum radiator will likely be lighter. Which will last longer I guess depends on the alloys selected and the cooling medium. | ||

| dave handa (Davehanda)

Intermediate Member Username: Davehanda Post Number: 1982 Registered: 5-2001 |

In my instance, my 328 had to have the radiator "rodded out", which entails the removal of the bottom, and running a long brush up each of the tubes, to clean out the crud. Apparently the flow is not terrific up to the radiator, so stuff can get settled in there. Weld the bottom back on, and all is well. No further cooling issues. So a recore may not always be necessary, but if stuff looks corroded, then by all means....Julio, you live in one hot place! | ||

| Julio Valladares (Jbanzai)

Junior Member Username: Jbanzai Post Number: 104 Registered: 2-2002 |

Now I have doubts again. So I was right, about copper properties, it is a better heat conductor that aluminum. But for your response Bill, looks like to have similar efficiency a copper raditor has to have thicker materials to last long enough, which will make it less efficient and heavier, am I right? Thanks Vermel for your suggestion. I took the car to a place where they could re-core my radiator this morning. However they told me what I suspected by the aspect of it. The raditor tanks walls and tubs are rather thin due to corrosion and they can not warranty how long will last. They also mentioned that it had been repaired or recored at least once. They told me that appart from age the previous owner might had use the wrong coolant mix who had litteraly eated the metal. This rised some more questions, as I do not know what coolant I will have to use if I replace the radiator with an aluminum one. Is there any other copper parts in the cooling circuit? If so, I will have a conflict on what coolant to use, as the ones who behave well with cooper does not seem to do well to aluminum, and viceversa. If so it will be smarter to repair it or get a original replacement part. Julio. | ||

| Verell Boaen (Verell)

Intermediate Member Username: Verell Post Number: 1215 Registered: 5-2001 |

Julio, A re-core amounts to a complete rebuild of a radiator. If the shop does it right, all dents will be taken out of the upper & lower tanks, then the radiator will be repainted & look & work like a new one. I suspect that a re-core with an additional row of tubes will work at least as well if not better than a custom Al one at about half the cost. Only way a re-core wouldnt work is if your tanks are severely corroded and just won't hold up. | ||

| Bill Sebestyen (Bill308)

Member Username: Bill308 Post Number: 545 Registered: 5-2001 |

Copper has about twice the conductivity of aluminum, an important consideration when designing cooling systems and especially fin geometry. All else being equal, copper is a better material for radiators than aluminum based on conductivity. The big questions are corrosion resistance and radiator design. A buildup of corrosion on the interrior of the cooling tubes will degrade the convection process, heat transfer from the fluid to the tubes. If corrosion can be ignored, a copper radiator of the same design will be superior. | ||

| Scott Anderson (Srandrsn)

Junior Member Username: Srandrsn Post Number: 200 Registered: 4-2001 |

Also check out www.alumrad.com They made one for me and I've been very pleased. They are in Michigan | ||

| Julio Valladares (Jbanzai)

Junior Member Username: Jbanzai Post Number: 99 Registered: 2-2002 |

Thanks Erich and Verell, After your comments I think I will go for an aluminum radiator replacement. I have droped some emails to the only 2 places I know, Ron Davis and Griffin, and I am now waitting their reply to my questions and pricing. I thought about a re-core, however my radiator does not look very good, and sooner or later I will have to replace it. I have to clarify that my car has near 70.000 miles on it, and it is the original radiator. I also like the idea of having a more efficient raditor, as I live in Madrid now. This summer we reached 115 F and even in some points of the city 125F for a couple of hours a day. For about almost 4 weeks we had nights always over 95 F, I am not joking, it was a very hot summer. So I think I could use a more efficient radiator, as whenever I drove the car out I had the fans comming on all the time. Thanks for your help. Julio. | ||

| Erich Coiner (Erich)

New member Username: Erich Post Number: 15 Registered: 9-2003 |

Julio, Ron Davis can make a radiator to a drawing. People in the Sunbeam Tiger community have had a lot of success using Aluminum radiators to cool down a hot cat. I read an article about a man who used a Ron Davis radiator in his Tiger. It worked so well he added air conditioning. His car keeps its cool in Phoenix Arizona all summer long. And he keeps cool too! He took his Tiger radiator in to Ron Davis and the comment was "So that's what a real one looks like. I have been making Tiger radiators from a print for a guy in LA for years and years." | ||

| Verell Boaen (Verell)

Intermediate Member Username: Verell Post Number: 1203 Registered: 5-2001 |

High performance radiators are generally made of aluminum. When you're dealing with very thin pieces of metal such as radiator or intercooler tubes & fins, heat transfer effects between the metal surface & the fluid often dominate the overall heat transfer. I remember reading about a japanese heat exchanger that was improved by replacing metal tubes/fins with paper ones! Seriously consider having your radiator rebuilt. Several Fchat members have had their radiators re-cored with over-size cores that have an extra row of tubes. The cost was only a couple of hundred US$. Search the archives for 'radiator' and 'core'. | ||

| Julio Valladares (Jbanzai)

Junior Member Username: Jbanzai Post Number: 98 Registered: 2-2002 |

Thanks Erich, I knew them, they have a web page http://www.rondavisradiators.com/, I am waitting for their reply on an email I sent them earlier today. However distance is an issue for me, I am in Spain, and sending my raditor means I won't drive my Ferrari for a long long time, in this case I rather pay a bit more to get an already manufactured radiator. However price is not my main concern, something that advertisment says sonuds strange to me. I always thought that copper had better heat transfer qualities than aluminum. At least has better heat absortion qualities. So I understund what the add says about wheight and durability, that is clear to me. But the heat dissipation question is not that clear. So I was wondering if somebody has tried an aluminum radiator in their 308/328 and what is his experience. | ||

| Erich Coiner (Erich)

New member Username: Erich Post Number: 14 Registered: 9-2003 |

Call these guys: Ron Davis Racing Products 7334 N. 108th Ave Glendale, AZ, 85307 (623)-877-5000 They can make a radiator to a drawing, or send you old one in. My guess on price will be around $400. It will not matter to them what car it is for so don't tell them. | ||

| Julio Valladares (Jbanzai)

Junior Member Username: Jbanzai Post Number: 97 Registered: 2-2002 |

Have anyone fitted a custom made aluminum raditor in their 328/308? Is it a good idea? I saw this on EBay http://cgi.ebay.com/ebaymotors/ws/eBayISAPI.dll?ViewItem&rd=1&category=33602&item=2434105577 and as my radiator is about to break and I need to replace it, I was thinking on replacing it with one of those. But I do not know if it is a good idea or not, if the price is right or too expensive, or even if there are more alternatives. My only reference is the original par which is way more expensive, and in my opinion not very efficient. Any comments will be welcome. Thanks, Julio. |