| Author | Message | ||

| Mark Eberhardt (Me_k)

Member Username: Me_k Post Number: 414 Registered: 5-2002 |

Thanks, I like yours too, it does a better job getting cars in. For me shop space is pretty important, I'm always trying to do something I shouldn't be to my poor car. The shop needs to be heated in this part of the country too, but it's better not to heat the parking to keep the rusting slower. I'm also considering turning the last car 90 degrees and moving the tools/machins to one side, that would get the foot print down to 36 square with the shop being 16 x36. That really only matters because it's attached and I'm putting a master suit above the shop area and I want to be reasonable on the room sizes. | ||

| Rob Lay (Rob328gts)

Board Administrator Username: Rob328gts Post Number: 3662 Registered: 12-2000 |

I like it, I think I like it better than my design. | ||

| Mark Eberhardt (Me_k)

Member Username: Me_k Post Number: 413 Registered: 5-2002 |

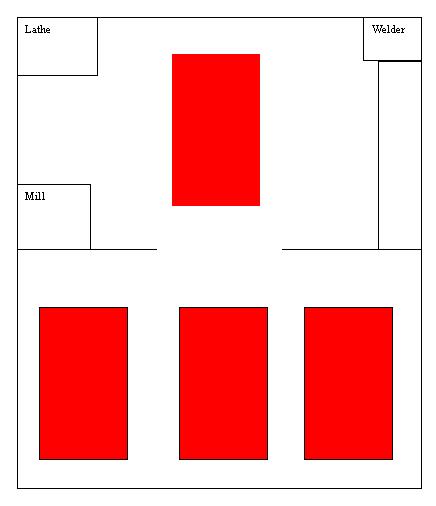

I've been thinking about the same size, but a little different layout.  | ||

| David P. Smith (Dave330gtc)

Junior Member Username: Dave330gtc Post Number: 77 Registered: 3-2002 |

Concrete flatwork is obviously priced differently around the country but in our area $2.25 per square foot for labor and materials is a rough guide. The customer is responsible for providing adequate access to the jobsite. A concrete truck fully loaded can weigh 70,000 lbs. Just because your pickup truck can get around the jobsite does not mean the concrete truck can. I also want to point out that no matter what the remodeling shows tell you on tv, concrete finishing is not a do it yourself project and should be left to the professionals. | ||

| Rob Lay (Rob328gts)

Board Administrator Username: Rob328gts Post Number: 3635 Registered: 12-2000 |

Good question, I hope the slab is included. | ||

| Horsefly (Arlie)

Member Username: Arlie Post Number: 784 Registered: 5-2002 |

Does that cost INCLUDE the concrete slab? About 15 years ago, a friend of mine built a 30' by 40' garage and the concrete slab cost him $3000 at the time. And that was after he built the pouring lumber and installed the re-bar himself that he had scrounged from scrap yards for years. What do concrete slabs cost today? I ran across another guy who had a concrete truck come out to pour his garage slab, and the concrete truck got STUCK in soft ground about 100 feet from the pouring site. So the truck driver tells him that it's HIS fault that the truck got stuck because it was HIS soggy ground that caused it. So if he wanted HIS concrete, he would have to pour it into a wheel barrow and run it over to the slab site and pour it out, because the truck was stuck badly. Otherwise, he was out the money for the concrete. Poor guy made dozens of trips with his wheelbarrow, and the concrete was starting to congeal about half way through the process. The end result looked awful. | ||

| PSk (Psk)

Junior Member Username: Psk Post Number: 158 Registered: 11-2002 |

Rob, Awesome, now I will take a print out and show this to my wife, as this is exactly what I want/need (  ) ... the problem is she might get too much of a fright. ) ... the problem is she might get too much of a fright. Thus need to somehow buy the right property that has enough space (in Sydney ... er, this will not be easy) so I can build THAT workshop. I do not think I will be able to justify moving the family out of Sydney just because I need more space for the workshop ...  Pete | ||

| Pat Pasqualini (Enzo)

Member Username: Enzo Post Number: 252 Registered: 2-2002 |

Don't forget the extra 750 they get you for the weather vain on top. | ||

| Rob Lay (Rob328gts)

Board Administrator Username: Rob328gts Post Number: 3628 Registered: 12-2000 |

well, 40' by 36' by 12' with standard options (few windows, doors, colored siding) is $20-25k. The limestone front and insulated finished walls inside will jack it up $5-10k more. | ||

| Randall Booth (Randall)

Junior Member Username: Randall Post Number: 113 Registered: 1-2003 |

If you don't mind saying, what does a building like that cost? | ||

| Rob Lay (Rob328gts)

Board Administrator Username: Rob328gts Post Number: 3622 Registered: 12-2000 |

I don't want a lift to park cars on top of each other. That's just for the workshop. Two deep, not high. | ||

| Vince (Manatee)

Junior Member Username: Manatee Post Number: 157 Registered: 6-2002 |

Paint me green with envy for you even being able to THINK about doing this. The pitch of the roof makes me think that multicar lifts are out of the question if you are going to park cars two deep. | ||

| Jim E (Jimpo1)

Intermediate Member Username: Jimpo1 Post Number: 1354 Registered: 7-2001 |

Rob, if you want to get into your house/garage faster, get your wife out of school and put her to work! :-) | ||

| Sean Ruckel (Sruckel)

Junior Member Username: Sruckel Post Number: 169 Registered: 10-2001 |

Hey Rob, if you want to come out to my brother's place someday and check out his shop and compare size, etc. you're welcome to it. He rents out the smaller one which he built first, but you can still check it out to compare as well. It's a custom made metal building and I don't think it was too terribly expensive. Some guys from Oklahoma, if I remember right, came down and did it. | ||

| Martin - Cavallino Motors (Miami348ts)

Advanced Member Username: Miami348ts Post Number: 3867 Registered: 5-2001 |

Rob, great choice. I would like to add though that you should consider having another garage door to the rear as basically a drive through. This gives you a lot of options and will set you back only the price of the garage door $1000 if you plan for it right away. Think about it. You can create later maybe a paved area behind the garage to tempraty store cars, or add easy to the garage and have already the opening. Proper planning will resolve a lot of headacks later. If you do not want to put the opening yet, at least have them build in a header as if you put a garage door so you do not have to do structural later at extreme costs. Then you just have the door cut out and are ready to go. I'd do it right away if I were you! | ||

| Bryan Phillips (Bryanp)

Junior Member Username: Bryanp Post Number: 57 Registered: 8-2002 |

Rob - this may be overkill, but I have separated my garage/shop into a 'clean' shop and 'dirty' shop. The dirty shop is where parts get degreased, the sandblasting cabinet, the polishing/grinding/wire brushing wheels all live. The clean shop is where the F-car is parked and where re-assembly happens. Since I was building from scratch like you will be, I built an engine hoist beam into the ceiling that spans the width of the garage. We also installed black iron lines for compressed air with three hook-up locations. Leave room for bulky things like the sandblaster, rolling tool box, mig welder, stand-up compressor - they eat up space fast. During excavation, run two separate underground conduits from the main house - one for your power to a new subpanel, and the other for misc items like phone, intercom, cable, other structured wiring, etc. When pouring the slab, put a vapor barrier and rigid insulation underneath the slab. Limiting the vapor transmission throught the slab will greatly assist the adhesion of whatever flooring finish you decide to apply, and the comfort level will increase w/ the insulation (although this may be minimal since you're in Dallas). Vented skylights w/ UV protection, low e coating and a translucent finish are a relatively cheap way to get some even natural light into the space. just my .02. | ||

| BobD (Bobd)

Intermediate Member Username: Bobd Post Number: 1025 Registered: 3-2001 |

Rob, it looks great... just remember one thing. 36 feet isn't as deep as you might think if you plan to park cars two deep. I believe you and Jenni have a Tundra, right? The Tundra is over 18 feet long. I have a "normal" garage and it's 22 feet deep... I wish I had another 3 feet just for normal parking. | ||

| Pat Pasqualini (Enzo)

Member Username: Enzo Post Number: 251 Registered: 2-2002 |

The Morton buildings are pretty good. My in-laws did a 30X36 up north and would be a great workshop/garage if the inside was finished off. | ||

| BretM (Bretm)

Advanced Member Username: Bretm Post Number: 3167 Registered: 2-2001 |

Looks cool as hell to me. | ||

| Rob Lay (Rob328gts)

Board Administrator Username: Rob328gts Post Number: 3613 Registered: 12-2000 |

Well, I realized how poor I was, the economy still is crap, and maybe a 2000+ square foot showroom/workshop with tile flooring, enclosed workshop with see through windows, built in bar/game room, and etc. is not the most logical thing to do. Especially since our house now is only 800 square foot and 80+ years old. The less we spend now, the quicker and nicer our new home will be next year. Well, it took a few weeks to come off the high of my $110k garage, but then the wheels started turning again. What if I just built a workshop that would have some extra storage and parking space. I got Jennie to agree that when we build the house I can still do my "showroom" garage. So now since it's just a workshop, let's make it cheap. I had worked with Tuff Shed before, but I decided to look at the metal Morton Buildings this time around. Price about the same, but they have more options, metal building will make for a better workshop, and I can get a limestone front to match the future house. Here's the layout I'm currently considering...  I went with the 3 single garage doors as I think that looks good, kinda like the Marriott garage. I have it at 36' deep so you can comfortably park cars two deep. I put one of the garage doors off to one end with the person door in-between. This door will be for the workshop entrance. Eventually I could see the garage space becoming more storage than to hold cars when we get the house built. I'll put the lift in about the middle for plenty of room with my main workshop area right behind. Right now the specs are... 46' by 36' by 13' 3-4 windows (3) 9' garage doors 1 person door 110 and 220 electrical plumbed for future sink Here's a pic to show you what I mean by the limestone front and sorta how we'll separate the 3 garage doors....  |