| Author | Message | ||

| Mitch Alsup (Mitch_alsup)

Member Username: Mitch_alsup Post Number: 872 Registered: 4-2002 |

"Do you know the rockwell rating?" No, and I am not 100% sure that they are titanium, but my thought process is something like: The valves themselves are titanium, There is a weight advantage to titanium retainers, Titanium can be obtained (metelurgically) so hard that is almost impossible to machine, Titanium can be surface hardened (as you indicate) or work hardened by machining So as long as the retainer is harder than the valve itself (by 10 Rockwell units) any galling should be on the valve itself not on the retainer. However, Ferrari knows what it is doing (but then so does Hon-duh) | ||

| Hubert Otlik (Hugh)

Intermediate Member Username: Hugh Post Number: 1033 Registered: 1-2002 |

mitch: re: Ti retainers. Do you know the rockwell rating? Some of us here in the hon-duh camp have had trouble w/ retainer galling when used in "high stress" application; i.e., 9000 rpm + use. Stock retainers on DOHC VTEC motors are hard (Rockwell 62), but they are not as strong as titanium. And although titanium retainers are stronger than hardened steel, they are softer (Rockwell 56) and prone the the galling. So, some have begun using Titanium Nitride coating to increase the hardness of the titanium to Rockwell 85, much harder than even the stock retainers. The coating is only 3 micron thick (.003mm) and shouldn't offset the weight of the valvetrain too much, an incidental bonus of using Ti retainers. Mitch? | ||

| Mitch Alsup (Mitch_alsup)

Member Username: Mitch_alsup Post Number: 861 Registered: 4-2002 |

Forgot to mention that the exhaust valves already have 3 angles, while the inlet valves have a 2 angle cut. So there might be a tiny amount of gain to be had with a full 3 ange valve job. But to to do this will require you to accept less than 2mm of seat width. | ||

| Mitch Alsup (Mitch_alsup)

Member Username: Mitch_alsup Post Number: 860 Registered: 4-2002 |

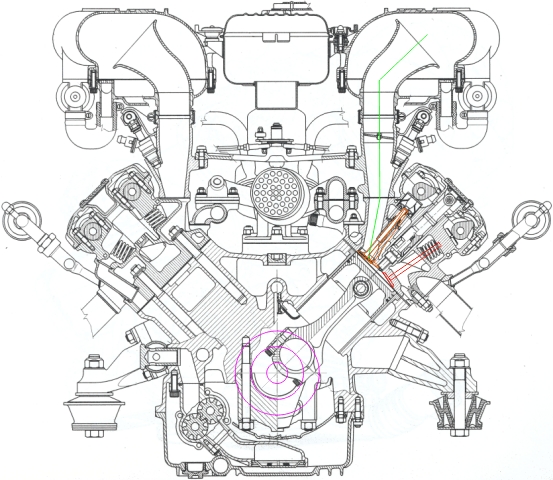

"Are these engines so well machined from the factory that aftermarket improvements are impossible?" No, however, the factory produces an engine with very good balance, and it is plenty expensive to do a better job. You should think of the basic run of the mill Ferrari engine as being built (tollerance wise) about as well as your basic SuperBike engine. Cylinders are true, round, with hardenerd surface. Pistions are forged aluminum aloy, exquisitely machined to 0.01 mm, balanced. Connection rods are forged titanium and carefully sorted into groups of 4 gms. Crankshaft is turned and ground out a piece of forged billet steel, then heat treated, and nitrided on the journals. An oil galley shoots cooling oil at the back side of each piston. Heads are a marvel of minaturization, and only partially water cooled (a lot of head cooling comes from the oil system.) Air flows strainge down through a velocity-like trumpet, right straight into the combustion chamber. Exhaust flows straign out into a tuned header. There is basically no way to remove weight from the valve train or to stiffen the valve train. Valves are titanium, retainers are titanium, springs are exotic steel, the hydraulic tapets only occupy ~0.3" thickness between the cam face and the valve back side. Heck, its already dry sumped!  Other than a few standard race prep crafting work, not much is left undone from the factory. In addition, if you look at the figure, look closely at the walls in the head. There is not enough rool to do anything other than touchup porting, port matching, and polishing. | ||

| Jeffrey Wolfe (86mondial32)

Member Username: 86mondial32 Post Number: 349 Registered: 5-2003 |

As a gear head from way back I was curious that I never seem to see, or read, of anyone doing the usual blueprint and balance tricks to a Stock Fcar engine. Even the factory rarely makes internal changes usually opting to uprate displacement. Carb's to Injection.. yes. Ignition and computer control yeppers... but rarely improvements to the basic design. Are these engines so well machined from the factory that aftermarket improvements are impossible? As an example... the basic 308 gained more valves and injection but no major changes in the crank or cams or rods. Reading the posts it seems that all that is discussed is Tubi and test pipes with perhaps a chip or mapp changes. If this is the case It only makes these cars that much more incredible. |