| Author | Message | ||

| J. Grande (Jay)

Intermediate Member Username: Jay Post Number: 1001 Registered: 10-2001 |

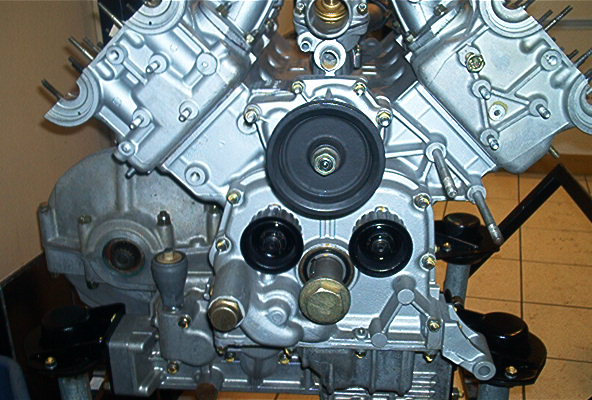

Dave, before the Previous owner "rebuilt" the engine it had severe oil leaks. After washing and scrubing all the encrusted oil and dirt off of the engine it was surprisingly clean. I guess the oil protected it from corosion. I did however repaint some of the parts that were discolored with a natural looking aluminum paint (nothing worse than having a "fake" looking aluminum color). I've found though that nothing beats elbow grease! Some of my bolts were covered with so much oil that when they were cleaned they still had their original plating in tact! Ric, all my stuff was also replated as per original. | ||

| Ric Rainbolt (Ricrain)

Member Username: Ricrain Post Number: 422 Registered: 2-2002 |

I generally don't replate 10.9 or 12.9 bolts. FWIW, all the fasteners or components I plate (or replate) were originally plated by the manufacturer in the same manner. I guess the big question is, does replating cause further emrittlement? | ||

| JRV (Jrvall)

Member Username: Jrvall Post Number: 661 Registered: 11-2002 |

Paul, Thanks for that info. Chrome Plating also has it's negatives, Nitrogen Embrittlement, and should be used with caution. | ||

| Paul Hill (348paul)

New member Username: 348paul Post Number: 19 Registered: 12-2002 |

Please read this message. Taken from http://www.boltscience.com/pages/glossary.htm (Start of quote) Hydrogen embrittlement Steel fasteners exposed to hydrogen can fail prematurely at a stress level well below the materials yield strength. Hydrogen embrittlement occurs in fasteners usually as a result of the part being exposed to hydrogen at some time during its manufacturing process but it can also occur through in-service corrosion. Electroplating is generally considered to be a major cause of hydrogen absorption in steel fasteners due to the release of hydrogen during this process. Higher strength steels are more susceptible to hydrogen embrittlement than lower strength steels however it is considered that there is no lower strength limit. However, as a rule of thumb, steels below Rockwell C 35 are considered to be far less susceptible. Tests such as the incremental load hydrogen embrittlement test can be completed to assess if hydrogen embrittlement is present in a batch of fasteners. (End of quote) The above is a very frightening reminder to everyone NOT to electro plate any bolt over or including grade 10.9 for a 100% guarantee that it will not suffer premature failure. I have been on the receiving end of hydrogen embrittlement and believe me it is no laughing matter. There is a vast amount of info on the web regarding plating of fasteners and alternative protection for high tensile bolts (zinc flake etc.). All the above is posted for a genuine concern for all my fellow members of this Forum. Paul | ||

| Richelson (Richelson)

Member Username: Richelson Post Number: 838 Registered: 12-2001 |

Rub and buff works well also. | ||

| Dave Penhale (Dapper)

Member Username: Dapper Post Number: 504 Registered: 4-2002 |

J grande, did you use an ally paint product (Eastwood Aluma Blast?) on that block and heads? If no, what process was used, looks fab! | ||

| Dave Penhale (Dapper)

Member Username: Dapper Post Number: 503 Registered: 4-2002 |

...and don't forget to retouch the recesses in the black screw heads with matt or satin black (as applicable) and 000 brush after the screwdriver has done its job! Nothing worse than bright shiny areas drawing attention to the myriad of black trim screwheads | ||

| J. Grande (Jay)

Member Username: Jay Post Number: 999 Registered: 10-2001 |

Lou, yes most of the stuff was originally yellow, but some is "silver" if you look carefully and the old stuff you can usually tell which it was. I bought a large sheet of aluminum and had it bent for a new firewall, no dings or scratches now, also painted the fuel tanks. | ||

| lou staller (Lou_staller)

New member Username: Lou_staller Post Number: 7 Registered: 12-2002 |

Thanks for all your tips. I like the yellow plated clamps and small parts. Was that a what the factory used, yellow? I'm in SoCal so I might have a problem finding some one in the area that can do 'colors'. I have used a company in the area to do just the plain silver zink and cadmium plating but never asked about a color. I don't know if the wonderful LA Basin EPA put the cabash on platers lately but I'll find out soon enough! How about different bulkhead materials. Anyone change theirs? While I've got the car down to it's bear bones I really want to replace the factory stuff. Any suggestions? | ||

| Ric Rainbolt (Ricrain)

Member Username: Ricrain Post Number: 417 Registered: 2-2002 |

I've used the Eastwood Cadmium simulation paint, only because I had to on a couple of parts that couldn't be replated, and were far too expensive to just replace. IMHO, I consider the product marginal. I've seen it on concours cars, and being a 3x8 series judge, I would dock points for it. It's not hard to spot. Proper yellow Zinc plating is not expensive (I had 188 parts plated for $45). Yellow Cadmium is a bit more (something like $75). | ||

| Jerry W. (Tork1966)

Member Username: Tork1966 Post Number: 366 Registered: 7-2001 |

Jeff, I got my braided hose from Evans automotive in Columbus. Ric, I know about s/s being softer than hardened steel. I would never use s/s in any high stress area. It's good that you pointed that out though for those who do not know this....could be very dangerous. I think I'll do that plating thing to my calipers as long as everything is apart right now. I have a buddy that owns a huge plating shop. I go there after hours and pay him in beer. | ||

| Matthew F (Mateotnt)

New member Username: Mateotnt Post Number: 12 Registered: 7-2002 |

Eastwood has a paint kit to simulate cadmium plating that holds up well if the parts have been properly cleaned. For similar under-the-hood cosmetic work, they have a black oxide plating system that I haven't tried yet but looks good. www.eastwoodco.com | ||

| Ric Rainbolt (Ricrain)

Member Username: Ricrain Post Number: 415 Registered: 2-2002 |

Zinc and cadmium plating is only done in commercial shops in the US due to EPA regs (most forms of plating, in fact). Find a place that services airplanes, and use the shop they recommend. The place I use is FAA certified or something to that nature. | ||

| Greg Rodgers (Joechristmas)

Member Username: Joechristmas Post Number: 610 Registered: 3-2001 |

How do you plate them? Do you take it to someone or can it be done yourself? | ||

| J. Grande (Jay)

Member Username: Jay Post Number: 993 Registered: 10-2001 |

Ric, I did the same thing to my calipers! Looks great! | ||

| Ric Rainbolt (Ricrain)

Member Username: Ricrain Post Number: 414 Registered: 2-2002 |

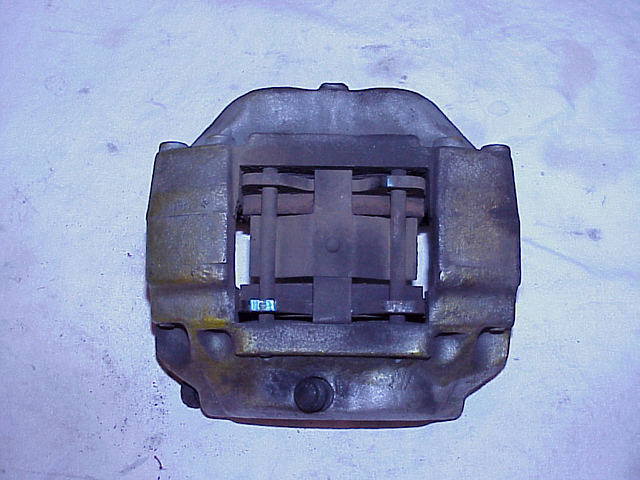

I know this is a cluttered shot, but here's some stuff I plated when I was doing the TR.  In the upper right corner you can see the brake calipers (after). Below is a "before" picture of the same calipers.  Most stuff was plated with Yellow Zinc, but the calipers were done in Yellow Cadmium. | ||

| Ric Rainbolt (Ricrain)

Member Username: Ricrain Post Number: 413 Registered: 2-2002 |

Jerry said "All nuts and bolts that I remove get replaced with s/s whenever possible" Not all fasteners should be replaced with stainless. The most common grades are A2 and A4. Do NOT use them any place Ferrari used a high-strength bolt or nut (10.9 or 12.9) as the A2 and A4 are not strong enough. Also, they seem to embrittle when exposed to heat cycling. I replaced some of my exhuast bolts (from the header to the catalytic and catalytic to the muffler) with SS, and several failed within months. I think your fine as long as you stick to "low stress" items: valve cover nuts, plenum or carb nuts, etc. I would NOT use them on any suspension component, nor on the clutch bell housing, or any other stressed application. | ||

| J. Grande (Jay)

Member Username: Jay Post Number: 988 Registered: 10-2001 |

Instead of replacing the original nuts, bolts and washers, I put mine on the wire brush and got all the rust and scum off of them. Then I sent them out to be replated (yellow), they look better than new. I did this with all the original brackets, fittings and hinges. My motor has been thoroughly cleaned and all hoses have been replaced (original look). Becareful when you reroute some of the hoses and harnesses. Ferrari did it the way they did for a reason. You don't want things rubbing or getting too close to heat, especially the fuel lines. My carbs have also been taken apart and all the little bolts and nuts have been replated. My air box assembly was also re-crackled and painted black. All my suspension has been removed, blasted and painted semi-gloss black. The firewall got a new sheet of aluminum and all of the harnesses have been cleaned. There is really no need to paint valve covers or the block(I hate that) the aluminum is beautiful enough. Here are some pictures of my progress...   | ||

| Jeff Green (Carguy)

Junior Member Username: Carguy Post Number: 154 Registered: 10-2002 |

Hi Lou and Jerry, I'm in the same club as you guys. I've been slowly getting my TR to "show" better by doing the same kinds of things you have done. I have been re-routing wires and hoses to clean up the engine bay as much as possible. I have stripped off that nasty undercoating, and will repaint the frame satin black. I would like to see more postings about activities like this, but their doesn't seem to be much interest in detailing projects. Jerry...where did you get new braided hose at? Also, what about the stainless nuts and bolts? I would like to see a forum catagory for postings on cleaning and detailing. It would be great to trade secrets and share knowledge. Most people think detailing is just "good cleaning". But for those that really know, it is actually an art form. Give a new cars to an "average" person and a true "detail" person, and look them over in say 5 years. The average car will have scratchy paint, filthy wheel wells, and a grungy engine bay, even though the person "washed" their car regularly. The detail car will look new, practically showroom clean. Ooops, I guess I better stop, didn't mean to get carried away. | ||

| Jerry W. (Tork1966)

Member Username: Tork1966 Post Number: 362 Registered: 7-2001 |

I had my rear valve cover, air box and support brace powder coated black and my rear header (because it's the only visible one) is now at Jet Hot getting their brilliant finish on it. This will also increase exhaust flow and reduce engine bay temps. They say a 3% h.p. increase is not out of the question. All nuts and bolts that I remove get replaced with s/s whenever possible. My "A" arms are now getting powder coated semi gloss black and my shocks are at True Choice getting rebuilt/repainted. I also painted all around the flat horizontal areas (where spec tags are) with semi gloss black. I took out all of my carpet in the trunk last summer and steam cleaned it and re-glued it in. It looks 100% better. In fact, I was ready to throw this carpet away! You'd be surprised how a good cleaning will restore the life of old looking carpet. I also sprayed it with that black carpet dye in a rattle can. Then put a new trunk cover on. Also replaced all braided hoses with new and polished my rear timing belt cover with aluminum polish. Other than that, I haven't done much in there. Sorry, I don't know anything about those hose routings. BTW, why would anyone shoot you? | ||

| lou staller (Lou_staller)

New member Username: Lou_staller Post Number: 6 Registered: 12-2002 |

I have to say I hesitate to ask this but I hope you guys will be OK with it. I am wondering what 'cosmetic modifications' some of you may have done to your 308 engine and engine compartments. My engine is now out and I want to improve the engine compartment looks and change some of the hose routings. I have a California emissions car thus have what seems to be 5 miles of hoses! I was thinking of re-routing those that I can to the lower front bulkhead, out of the line of sight. How about the water lines from the thermostat housing to the aluminum water pipe coming out of the chassis? Anyone know of any improvements that can be made there? Anything would be better then them laying on the engine between the cylinder heads! The Ferrari motor is absolutely gorgeous, if you can only see it! I really want to hide as many hoses as I can. How about the front and rear bulkheads? Has anyone replaced those 'cheesy' looking aluminum panels with something else? Possibly a satin or brushed aluminum or stainless material? (Not polished, just something clean and nice.) I'm not looking to 'customize' the car but just want to clean it up a bit. My wife already told me the car is going to my son, in time, so I don't have to worry about resale value! I'm detailed oriented so time and effort are not a problem. Any suggestions? And please, don't shoot me! |