| Author | Message | ||

| Jerry W. (Tork1966)

Member Username: Tork1966 Post Number: 380 Registered: 7-2001 |

Will do, thanks! | ||

| Steve Magnusson (91tr)

Intermediate Member Username: 91tr Post Number: 1348 Registered: 1-2001 |

Then you've just got to keep trying pressing/prying it off as uniformly as possible. | ||

| Jerry W. (Tork1966)

Member Username: Tork1966 Post Number: 379 Registered: 7-2001 |

Steve, #1. Thanks, Jerry | ||

| Steve Magnusson (91tr)

Intermediate Member Username: 91tr Post Number: 1345 Registered: 1-2001 |

Jerry -- I'll assume that you removed the single large bolt with the thrust washer from the center. When you say "it moves back and forth" do you mean that: 1) the spline joint is already free (sliding) in the home position but as you try to withdraw the axle flange it stops, or 2) the spline joint is frozen (and the "back and forth" motion is some other internal play)? | ||

| Jerry W. (Tork1966)

Member Username: Tork1966 Post Number: 378 Registered: 7-2001 |

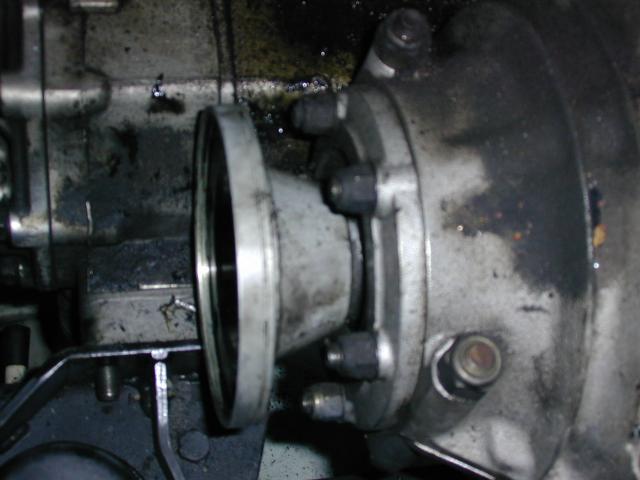

Guys, please tell me how to get this last cone shaped housing off in order to get at the shaft seals. It moves back and forth but seems like there is something stopping it. Thanks in advance. Jerry.  | ||

| Tom Bakowsky (Tbakowsky)

Junior Member Username: Tbakowsky Post Number: 173 Registered: 9-2002 |

Good tips steve!! | ||

| Steve Magnusson (91tr)

Intermediate Member Username: 91tr Post Number: 1335 Registered: 1-2001 |

A little 600~1000 grit refreshing of the seal contacting surface on the axle flange wouldn't hurt (i.e., simulating a fresh non-directional fine ground finish rather than a super-polished surface). I've also got in my notes to use some RTV (and the appropriate preparation) under the large thrust retaining washer for the axle flanges at both the bolt OD/diff output shaft ID area and at the spline joint area (as Fig 12 in the WSM shows these can be lubricant migration paths to the outside world), and a dab of Loctite 242 (blue, medium) on the axle flange-to-diff bolt threads (at 55-65 ft-lbs). Good luck with the project. | ||

| Jerry W. (Tork1966)

Member Username: Tork1966 Post Number: 371 Registered: 7-2001 |

Thanks Tom. | ||

| Tom Bakowsky (Tbakowsky)

Junior Member Username: Tbakowsky Post Number: 168 Registered: 9-2002 |

It's not hard just time consumming,and a little help from a friend would mak the job go much easier when unbolting the axels from the diff drive flange and the spindal assembly. Once you have both axels out you can GENTLY pry out the seals. To replace is a little tricky. You may have to buy a seal driver or use an old socket the same diameter of the seal and use that to tap it in place. Go slow and make sure the seal in going in straight. Before installing the seal take a little bit of grease and put some on the inside lip of the seal that surrounds the axel flange. | ||

| Jerry W. (Tork1966)

Member Username: Tork1966 Post Number: 367 Registered: 7-2001 |

How hard is it to replace these seals? I have oil weeping out from this area. Any tricks/hints/suggestions would be appreciated. Thanks, Jerry. |