| Author | Message | ||

| Dave Penhale (Dapper)

Member Username: Dapper Post Number: 585 Registered: 4-2002 |

Paul, Regarding sill plates, I personally wouldnt want to bother with the rubber inserts, but I think its important if possible to roll the plate down over the edge a little as is the standard fit. I guess a polished finish would be a disaster as it would get scratched up in short order, how about a kind of knurled look in a field within the plate (larger field than the current rubber insert). I am tempted to go for some Carbon fibre ones but it sounds like they dont wrap over the edge of teh sill so there is a bit of exposed area to get chipped away | ||

| Jean-Pierre D. (Jp348spider)

New member Username: Jp348spider Post Number: 18 Registered: 8-2001 |

Thanks a lot Paul. It will be just one more Spring project...an easy one it seems... Jean-Pierre | ||

| Paul Hill (348paul)

Junior Member Username: 348paul Post Number: 168 Registered: 12-2002 |

Jean-Pierre, There is no need to take the box out � You will need to remove the black shrouding that fits inside the front boot (the part that goes round the air box) Once that is off it is a 1/4hr job. I would take some pictures to show exactly how I done it. I will email you with the progress. Paul | ||

| Jean-Pierre D. (Jp348spider)

New member Username: Jp348spider Post Number: 17 Registered: 8-2001 |

Paul your price seems very fair. I would take care of postage also of course... Let me know if you decide to produce it. How do you take out the box itsef? straight up or, do you have do dismount other items first? Thanks Jean-Pierre | ||

| Paul Hill (348paul)

Junior Member Username: 348paul Post Number: 165 Registered: 12-2002 |

Jean-Pierre, I will work out a price for the brass part, bearing in mind that I would only make a few at a time, I would have thought that it would be around the �20 pound mark � A bit better than the $2000.00 !! � Let me know your thoughts. Dave, Great to hear you like the bits! � Always nice to get feedback! Hmmn - -now you have got me thinking!!! � The sill plate covers on mine are starting to rust around the holes � could be the next project! � After the dead pedals of course! � If only I had more time!! So just thinking out loud for ideas � But please don�t expect anything within the next 24Hrs !!! Aluminium, - soft as you know what � would it be appropriate in such a demanding area? � Anodise it? � Would give it a harder wearing surface, - could be anodised any colour. � Straight grain the surface before anodising? Stainless, - Not as easy to work with compared to Aluminium � Higher cost � less finishing options � Polished would still scratch up � Straight grained??? Steel � could be bright chrome plated � Whoooaaa!!! � You would be able to comb your hair before you got into the car!!! Any other suggestions? What about the Ferrari rubber part that sits inside the recess � Replicate the recess or do without?? Bob, I have had no experience with the blower motor, if you do get the motor apart I would have thought that they would have used a standard oilite bushing. Paul | ||

| J R K (Kenyon)

Junior Member Username: Kenyon Post Number: 234 Registered: 10-2002 |

My 348 Spider has genuine Ferrari Carbon Fibre door sills. Excellent. They are on the 348 GTC as standard. | ||

| bob snow (Resnow)

Junior Member Username: Resnow Post Number: 63 Registered: 5-2001 |

Paul, My motor seems to have worn bushings which cause quite a bit of shaft wobble of the squirrelcage blower and speed-dependent noise. Just wondered how difficult it was to get this motor out of the housing so I can repair it. Bob | ||

| Dave Penhale (Dapper)

Member Username: Dapper Post Number: 579 Registered: 4-2002 |

yep, sure is a bugger, getting those damn sill plates trashed are a big worry (I went to heck of a lot of trouble to get them refinished so I dont relish having to do it again) when having to take it to a dealer for any work. I took the sill plates off and taped cardboard in their place for the most recent main dealer visit, you guessed it, they even gouged the cardboard with their feet, vindicating my preventative measures! | ||

| Chuck Rine (Chuck348ts)

Junior Member Username: Chuck348ts Post Number: 144 Registered: 5-2001 |

Dave, I have had the same problem with my door sill plates - took them off stripped them down, sanded off the rust, repainted them with black trim paint, and now they are all scuffed up from getting in and out of the car, plus they are starting to rust again around the screw holes. A stainless or aluminum solution seem best. | ||

| Dave Penhale (Dapper)

Member Username: Dapper Post Number: 578 Registered: 4-2002 |

Paul, Sounds like another item to offer on your Ferrari section on Hill-Engineering website. BTW Love the Ally gear knob and pedals. Fitted the Knob at the weekend, looks awesome. Will hopefully get time to fit the pedals next weekend, instructions are very concise and great figs. Have you thought of designing sill plate covers or better still 'replacements' in Ally (or stainless) I've just had my satin black ones stripped/treated and re-enamelled but can't see them lasting long before they either rust again of get gouged by passengers feet! | ||

| Jean-Pierre D. (Jp348spider)

New member Username: Jp348spider Post Number: 16 Registered: 8-2001 |

It happened to me (348 Spider) last summer. I have not fixed it yet. I asked the local Ferrari dealer (lake forest Sports Cars) about replacement...you have to buy a new box at $2,000.00 !!! So I welcome your message.... Let me know how I can have that piece made | ||

| Paul Hill (348paul)

Junior Member Username: 348paul Post Number: 157 Registered: 12-2002 |

Jeff, It seems like a common problem on the 348, and from an engineers point of view it is under engineered. From what I have found when pressing either switch (Outside air/re-circulate), the ECU supplies the motor with a voltage for a specified time � around 10 � 15 seconds. (It just reverses the polarity when it needs to go the other way). There is no limit switch on the motor so it just turns the flap until it is hard up against either position. It usually takes less time than the 10-15 seconds that the voltage is supplied to the motor for the flap to get from one position to the other. With this in mind the plastic shaft is under a fair amount of strain. This is another reason I made the replacement from brass. I suppose it is possible that it could be broken due to someone pushing on it. It really could have done with some sort of slipping clutch type shaft coupling, but there again is only the air box! Bob, No problems with the fan on mine as of yet � Do you have a problem with yours? Bruce, The �� drive did enter my mind! Paul | ||

| Bruce R. Morehead (Brm)

New member Username: Brm Post Number: 20 Registered: 4-2002 |

Mine has been broken for a couple of years. I understand that a 1/4 inch drive extention may also work to replace the broken part. Since I always use interior air (cools faster in FL), I just put a cover on the inlet. Someday I will get a chance to fix it properly. | ||

| bob snow (Resnow)

Junior Member Username: Resnow Post Number: 62 Registered: 5-2001 |

Mine broke about 3 years ago and I have not gotten around to fixing it since I always use outside air if I even use the AC or heater at all. Nice fix and I think I'll try it soon. Have you had any problems with the blower fan? Bob | ||

| Jeff B. (Miltonian)

Junior Member Username: Miltonian Post Number: 183 Registered: 12-2002 |

Great post, Paul! I've seen a couple of these broken. I wondered if the flap got frozen in position, or if someone pushed it with their hand, or just how it became broken. I don't think it would break by itself. | ||

| Paul Hill (348paul)

Junior Member Username: 348paul Post Number: 156 Registered: 12-2002 |

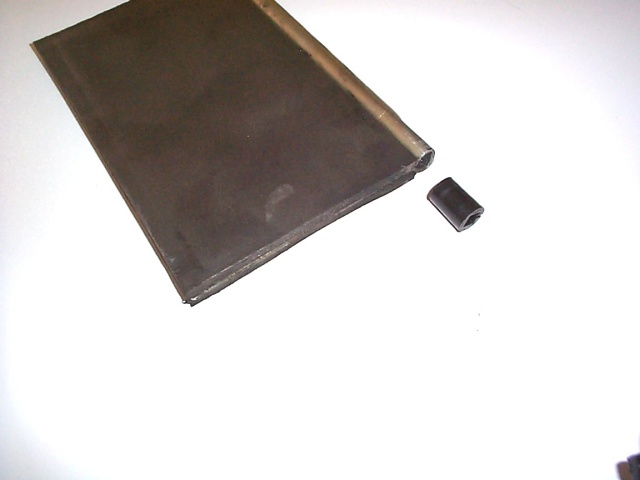

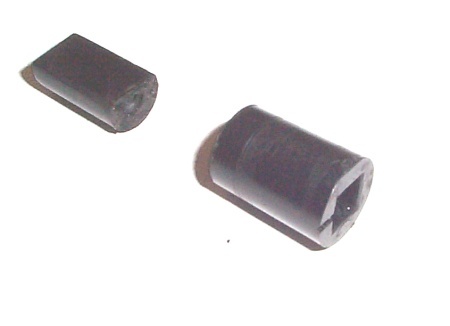

Thought I would try and find out why the air re-ciculation flap was not moving on my 348 � The motor was buzzing away, but no movement. The plastic shaft that goes from the motor to the flap had snapped in half!  Ferrari tells me that neither the flap or plastic shaft were available as a spare part! � I did not even ask the cost of a complete unit!! This is purely for others to see if they have the same problem and want to do a fix on it � I know its not life threatening function of the car, but none the less - great satisfaction when its all done. It is quite easy to get the flap out by unscrewing the 2 screws that hold the motor onto the side of the air box. There is a 6mm male square drive in the end of the motor that turns in either direction causing the flap to open and close. Once its all out it just needs a new piece made up � something that a machine shop should only take about an hour to do. I made mine out of brass as it is easier to broach the square in the end.   If anyone has to do this and has problems in getting a new piece made, email me and I will oblige. Hope this helps someone else!! Paul |