| Author | Message | ||

| Hans E. Hansen (4re_gt4)

Intermediate Member Username: 4re_gt4 Post Number: 1050 Registered: 4-2002 |

A little off topic, but I like the blown Pontiac motors. Very little boost and HP increase, but much of the improvement is available thru out the rev range. Almost has the torque of a big block off the line. Think big tractor motor. | ||

| Mark Eberhardt (Me_k)

Member Username: Me_k Post Number: 469 Registered: 5-2002 |

Ben, I think you made 2 really good points, one of which never really occurred to me before, if I'm understanding you right. The first, it�s hard to trust info the person trying to sell you something is giving you, they will always present it in the form that is best you them. The second, and the one I�d never considered is that drag racing is not a steady state game. When you look at the graphs, they say use the smallest blower you can and spin the snot out of it. That will give the best volumetric and adiabatic efficiency. On a drag car, it�s only a few seconds, so a big blower that starts the run cold will suck up a lot of heat and have a cooler discharge temp than the small one and make more HP. I think that might explain why I�ve been thinking don�t even think about going over 10 psi without an intercooler and you�re saying it won�t really do anything under 10. It all depends on what game you�re playing I guess  | ||

| Ben Millermon (Brainsboy)

Junior Member Username: Brainsboy Post Number: 217 Registered: 5-2001 |

Hans, When sales companys give us an efficiency to sell their blower, it can be misleading. For one, mechanical and volumetric efficiencies are hard to measure accurately while on a motor. Usualy when an efficientcy is given on a blower its an adiabatic efficiency. Just because a screw blower may have a better adiabatic efficiency doesnt make it better. You have to consider volmetric and mechanical efficiencys. Drag cars run only a few seconds they are not as conserned about adiabatic efficiency. Roots style blowrers typicaly have a better mechanical and volmetric efficiency then other style blowers, and thats why they are used on drag cars. Comparing Joe smow's blower to the one you saw at the Jones next door is difficult because not all companys use the same methods, not to mention a hand full of variables used at the time of testing. | ||

| Mark Eberhardt (Me_k)

Member Username: Me_k Post Number: 468 Registered: 5-2002 |

Top fuel dragsters and funny car have all been using screw type blowers for something like 10 years now. From the outside they look the same, but the rotors are different, in a roots the 2 are basically the same, in a screw type there is a male and a female. Here's a good propaganda link, but what they say is right. http://www.whipplesuperchargers.com/content.asp?PageID=65 The supercharged GM cars use eaton roots type. They are � the price of a screw type and fine up to 5 or 6 psi. That is a 40% HP increase, not to shabby. | ||

| Hans E. Hansen (4re_gt4)

Intermediate Member Username: 4re_gt4 Post Number: 1044 Registered: 4-2002 |

What's different about a screw compressor? I'm not sure that I've ever seen one. Why is the roots type used on dragsters, if it isn't as efficient? Is the blower found on Pontiac V6's a roots type? It looks like a mini-dragster blower. | ||

| Mark Eberhardt (Me_k)

Member Username: Me_k Post Number: 464 Registered: 5-2002 |

Hans, To expand on what Ben said, just the act of compressing a gas makes the temperature go up, that is the ideal temp and is the same for any compressor. Every compressor also has an efficiency curve, that is the % of the energy you put in that actually goes to increasing pressure, the rest mostly ends up as extra heat in the compressed gas. It is a compressor curve because the efficiency is different at different rpms and different pressures. A roots type blower is about 50% efficient at 5 psi, but only about 35% at 10 psi. A screw type compressor is about 65% at 10 psi and 50% at 20 psi. A centrifugal is about the same efficiency as a screw type, but just doesn�t make boost at low rpms. | ||

| Ben Millermon (Brainsboy)

Junior Member Username: Brainsboy Post Number: 212 Registered: 5-2001 |

Hans, on a roots style blower, it actualy compresses the air by beating the hell out of it. Its quite common for these style blowers to produce more heat. Keeping a motor streetable takes some work with a 6-71, now with the eaton or something smaller your not going to have the same amount of heat produced as a 6-71 but the design is the same. Heat is a blowers worst enemy. As the air heats it expands. A jar of 50c air will have more air then a jar at 100c. My race car will usualy run about .4 sec faster when the motor is cold. There are tricks to help, like using a larger CID blower underdriven or you could also add nitrous, nitrous will lower the air temp alot, the two together work wonders. However its WAY too dangerous on a ferrari motor, its kind of like giving your mother cocain its something you just dont want to do. | ||

| Hans E. Hansen (4re_gt4)

Intermediate Member Username: 4re_gt4 Post Number: 1041 Registered: 4-2002 |

Why is there a difference in temp rise Roots .vs. Screw-type blower? I would think air compression from any device would yield similar temp changes. | ||

| Charles I Claussen (Atlantaman)

Junior Member Username: Atlantaman Post Number: 108 Registered: 3-2002 |

again--pics not wanting to load    | ||

| Charles I Claussen (Atlantaman)

Junior Member Username: Atlantaman Post Number: 107 Registered: 3-2002 |

trying pics again here  | ||

| Charles I Claussen (Atlantaman)

Junior Member Username: Atlantaman Post Number: 106 Registered: 3-2002 |

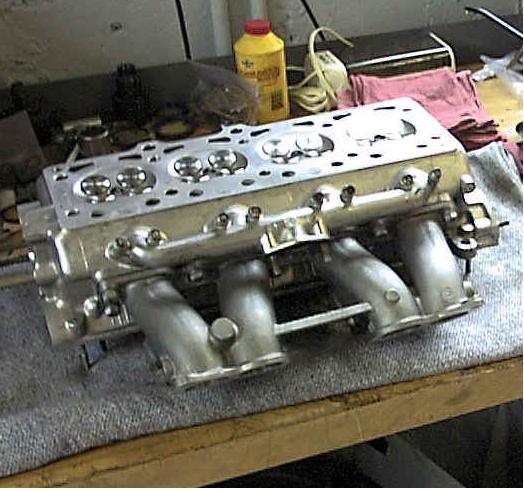

Just for your info--converting to EFI on a 3084v motor is a pain--I just finished doing one and the fuel rails and intake were not fun--took a lot of careful machining and welding. see pics below NOTES: 1)note spacer for throttle body to extend beyond fuel rail 2) not spacers to raise the Plenum 3) note the fuel rail itself4) note where intakes were machined down to install EFI injectors. | ||

| Mark Eberhardt (Me_k)

Member Username: Me_k Post Number: 463 Registered: 5-2002 |

Ben, Cool. A little over the top for me (sorry about the pun), but very nice. On the intercooler, 10 seems a little high. The eaton blower I was using is one of the most efficent roots type blowers and still had a 100 degree temp rise at 5 psi and about 220 at 10 psi, so I was sending 300 degree F air in to the engine, pretty hot. Usually when you start getting over a 100 degree temp rise, it's time to think about an intercooler, at 200 degree temp rise there usually isn't much choice. There's alway exceptions though. With a screw type blower, the temp rise is 100 degrees at 10 psi and 200 at 20 psi, so you can run a lot more boost on pump gas without an intercooler. The down side is they cost twice as much too. Really nice though. | ||

| Ben Millermon (Brainsboy)

Junior Member Username: Brainsboy Post Number: 209 Registered: 5-2001 |

I have gotten a few e-mail's about building this blower manifold with fuel injection. Just wanted to post right now my fuel injection system is not ready. I have alot of the electronic side done but was hoping to team up with Kermit in the future. As of right now everything is up in the air. | ||

| Ben Millermon (Brainsboy)

Junior Member Username: Brainsboy Post Number: 207 Registered: 5-2001 |

Mark, if you get a chance look at my profile and you will see my play toy, I think any 6-71 is going to be too big. The blower on my datsun stands taller the the roof.There is anouther company that makes a blower with the intercooler built into it. Its casing is acutaly made with cooling lines inside of it, its made by Kuhl but I dont even know if they are made any more, this is great for high boosts, but to be honest an intercooler is not even practical unless you are running over 10 pounds boost in a roots style blower. | ||

| Mark Eberhardt (Me_k)

Member Username: Me_k Post Number: 461 Registered: 5-2002 |

The B&M is a good unit, but quite tall once you put a carb of throttle body on top. I had an eaton mp90 which worked quite well and has an end inlet, so it fit under the stock hood. It is a roots type, I ran it at 10 psi. http://mywebpages.comcast.net/markeberhardt/MarkFerrari.mpg My new unit is a lysholm ax2300 from whipple. I'm putting an intercooler between the blower an plenum. I think I'll be able to put it to 25 psi, but may need to settle for 20. I'm still planning to get it under a stock hood. | ||

| Horsefly (Arlie)

Member Username: Arlie Post Number: 927 Registered: 5-2002 |

Ben, have you compared the traditional GMC 6-71 blower to the less common 6V-71 blower? I have a 6V-71 blower that I bought for a "someday" project. They are off turbo diesel 6 cylinder truck engines. They are slightly shorter that the traditional 6-71, and they mount differently with long bolts on the sides that go down into a mounting plate. | ||

| Ben Millermon (Brainsboy)

Junior Member Username: Brainsboy Post Number: 206 Registered: 5-2001 |

My heart wants to put a 6-71 blower on it, but reality quickly sinks in... I was thinking along the lines of a B&M blower because its still a roots style blower but its small and compact. | ||

| Mark Eberhardt (Me_k)

Member Username: Me_k Post Number: 460 Registered: 5-2002 |

Ben, Now you have my attention. Have you decided what goes on top of the intake yet? Here's the start of my latest effort, a lot of welding and grinding to do...   | ||

| Horsefly (Arlie)

Member Username: Arlie Post Number: 925 Registered: 5-2002 |

I think you guys have pretty much answered my questions. Somewhere buried in storage, I have a book that describes most of the older electronic fuel injection systems in detail. So I have actually learned something today. The K-Jetronic systems are not actually computer controlled nightmares. And the early carb setups will fit other 2 valve head motors. I guess that it's up to the old pocketbook as to which is easier to deal with. Just trying to be more informed in case I run across that 308 project car in the barn. What kind of supercharger are you putting on that engine? I guess you could cut the input holes for anything that would fit under the hood. How about an old Rochester fuel injection intake? (OK, sorry I suggested it.) | ||

| Ben Millermon (Brainsboy)

Junior Member Username: Brainsboy Post Number: 205 Registered: 5-2001 |

stage,,,, I wish this site had spell check  | ||

| Ben Millermon (Brainsboy)

Junior Member Username: Brainsboy Post Number: 204 Registered: 5-2001 |

There are other options, I am currently working on a Millermon Supercharger setup. Its still in the design stag but here is a photo of the proto type intake manifold for a supercharger. Although still in the designing stag I hope to finish it up this month. I have made the template for the blower hole but havent cut it out yet as you can see. Sorry about the crapy photos its the best I could get with this webcam    | ||

| Russ Turner (Snj5)

Junior Member Username: Snj5 Post Number: 62 Registered: 2-2003 |

The KJet is a continuous flow to the injectors with the flow metered by movement of the big airflow sensor plate in the fuel distributor BEFORE the throttle body. KJet is also synonymously called CIS, or Constant Flow Injection This flow is modified by temperature warm-up regulator, and in later versions by lambda. The system is primarily designed for emissions control, and has two main drawbacks as far as performance. First, the airflow is impeded by a circuitous flow route and that big dukin' airflow sensor plate that the engine has to suck past. (This is overcome in forced induction like the early 911 Turbos). The second is that since the airflow is 'mechanically sensed, the cam profiles cannot be to radical which would lead to air column pulsations that would 'confuse' the system. This is why the injected cams on all KJet cars are very benign (see my previous cam timing comparison post) with little overlap. For what it was designed to do in the era it was designed, it is brilliant and reliable (mostly). It's big sesitivities are fuel pressure, air leaks and cloggy injectors. Kjet is ubiquitous on same era VWs, Porsches, Volvos, MBs and many parts are interchangable. Hope this helps. best Russ | ||

| ctk (Ctk)

Junior Member Username: Ctk Post Number: 91 Registered: 7-2001 |

There is no computer in the K-Jet system. The WUR (warm up regulator)and the CPR (control pressure regulator) are the expensive bits in the system. The fuel feed is by constant pressure with bleed-off returning to the fuel tank. Air feed vs fuel feed controlled by the counterbalanced plate in the air intake system. The fuel pump in a K-Jet has to have about 95psi upwards to properly work. | ||

| Horsefly (Arlie)

Member Username: Arlie Post Number: 924 Registered: 5-2002 |

How does the K-Jetronic system deliver the fuel? Are the injectors merely small nozzles fed with pressurized, metered fuel, or does it use a solenoid activated fuel nozzle? And does the K-Jetronic system use some sort of electronic control module (with an associated replacement cost of big bucks)? | ||

| ctk (Ctk)

Junior Member Username: Ctk Post Number: 90 Registered: 7-2001 |

Just to add my two cents. The Bosch K-Jetronic system is electro-mechanical. in this sysstem, fuel measurement and flow works on the principles of hydraulics. It was fitted on up-market European cars in the the 70's till mid 80's when it was replaced with either the KE-System or the newer L, LH, Motronic systems from Bosch. Bosch had a fully mechanical system called D-Jetronic prior to the K-Jetronic. This was used in early Porsche 911E and some VWs | ||

| Russ Turner (Snj5)

Junior Member Username: Snj5 Post Number: 61 Registered: 2-2003 |

Arlie All K-jetronic on all 308 and 328 cars is considered mechanical despite the name. Sounds like a 2 valve retro fit would work fine - be sure to also get the water cross pipe as it also holds the linkage. For you two valvers that want to go to EFI, TWM (twminjection.com) makes the whole set up, about $4500 for the manifolds and throttle bodies - and no, they do not make a qv manifold (I asked).  | ||

| Horsefly (Arlie)

Member Username: Arlie Post Number: 923 Registered: 5-2002 |

Ben, thanks for the info. I was therefore falsely assuming that all the injected 308s used an electronic system. Hard to believe that Ferrari was using a mechanical injection system in 1980 when Chevrolet stopped using mechanical injection in 1965. What are the major components of the 1980 injection system? Does it use a mechanical fuel pump to feed the injectors, or a free running electrical pump? How is the fuel "metered"? Controlled by intake vacuum like some other systems? Am I therefore correct in assuming that a 1980 308 will have NO electronic control module for its injection system? | ||

| Ben Millermon (Brainsboy)

Junior Member Username: Brainsboy Post Number: 203 Registered: 5-2001 |

Arlie, The 2v 1980's are mechanical injection not electronic. | ||

| Horsefly (Arlie)

Member Username: Arlie Post Number: 920 Registered: 5-2002 |

Thanks for the input on my original question. Mark, you mentioned, "mechanical injection". Maybe I am incorrect, but I thought that all of the 1980 and later model 308 Ferraris had "electronic" injection with an electronic control module. My experince with "mechanical" injection comes from the older Rochester mechanical fuel injection as used on early Corvettes. Aren't all 1980 and later 308s "electronically" injected? And don't they all have a computer module to control the injector(s)? I personally don't really care that much for a computer in an older classic car. My reason for asking the original question was in case I run across somebody's 1980 up non-quad valve 308 that is not running because of electronic problems. Seems possible to simply get rid of all the electronic injection garbage and swap in a 77 to 79 carb setup and not worry about being a computer hacker in order to fix things. | ||

| Ben Millermon (Brainsboy)

Junior Member Username: Brainsboy Post Number: 190 Registered: 5-2001 |

Paul I have personaly talked with kermit, and we may be working together with my electronic fuel injection and his manifolds. We are trying to offer a system that can be reasonably priced so the average man can afford it without breaking the bank. | ||

| Paul Sloan (Sloan83qv)

Member Username: Sloan83qv Post Number: 539 Registered: 3-2001 |

While Mark is correct that converting to EFI is the best way to go for pure performance, I tend to agree with Russ and JRV that the Webers are very cool looking and nothing in the world sounds like a bunch of Webers sucking air at speed! Russ's conversion will most likely work very well with stock cams but for my conversion which is a little more radical I have new pistons,cams and major porting and polishing as well as direct coil to plug ignition system. Either way you go you first must open your wallet WIDE, VERY WIDE. By the way 2 valve manifolds will not work on a 4 valve head.  | ||

| Russ Turner (Snj5)

Junior Member Username: Snj5 Post Number: 58 Registered: 2-2003 |

Mark brings up a great 'debate' - carbs vs EFI. Having been through some research there is a spectrum of fuel delivery mods from modifing the Kjet, carbs, EFI, EFI with DIS, and forced induction.... Mark's costs estimates are a bit low from what I have seen for both the carb and efi, even with SDS keeping stock ignition, but he may have different sources. However, He's right for the absolute most control of the intake mixture EFI is the 'hot ticket'. I would recommend you first determine how you are going to use the car and go from there. For me, there was never another choice but my beloved Webers - not perfect, but what personality, elegance, cost effectiveness and reliability. Everybody has an opinion, usually extreme on FChat, (like I think aftermarket FI on Ferraris is dorky), so take mine with a grain of salt as well. It's your car - have fun! JRV once said that mods must improve something and look cool - I agree with that! best to all rt | ||

| Mark Eberhardt (Me_k)

Member Username: Me_k Post Number: 456 Registered: 5-2002 |

Personally I thing the hot ticket in that case would be to convert the mechanical injection to efi. It's not that hard to do, but would run around $3k....and you can get a use stock injection system for around $1k. I'd guess you'd spend at least $1k before you got it converted to carbs, buying everything used | ||

| Russ Turner (Snj5)

Junior Member Username: Snj5 Post Number: 57 Registered: 2-2003 |

The 2v carb intakes will not fit a QV. Paul Sloan and Kermit (See previous threads - with pictures) made up some intake manifolds and are going to Weber IDA carbs. Kermit and Paul both are very helpful and have a terrific project going. Modena Engineering (Frank Capo) in Austrailia used to sell beautifully cast dcnf manifolds for 4valve engines. I just purchased a set of 40 dcnf manifolds from Blackhawk to convert my 3.2 to carbs this summer. Not sure if they have any more. I have pictures of the manifolds at home if you are interested. Until then, here is a picture of the 4valve head with the injection runners - you can see the separate cooling manifold as Ben describes. The 2 valve incorporates the coolent exit into the intake manifold. Of course, with carbs you open up incredible cam possibilities and I could go on and on about jetting, but it's all in previous threads. Hope this helps Russ  | ||

| Ben Millermon (Brainsboy)

Junior Member Username: Brainsboy Post Number: 188 Registered: 5-2001 |

The carb intake will fit on an injected 2v motor, but you need to change the water transfer pipe thats connected to the intakes. Im pretty sure they wont fit the qv as the ports are different. | ||

| Horsefly (Arlie)

Member Username: Arlie Post Number: 918 Registered: 5-2002 |

Can a carbureted intake off an early 308 be transplanted onto a 308 injected engine? Will a carbureted intake off an early 308 fit a quad valve engine? In some states, such a swap would probably fail smog laws, but others wouldn't care. Just wondering about the cost comparison of repairing a non-functioning injection setup versus replacing the whole intake with an earlier carbureted setup. |