| Author | Message | ||

| Bill Sebestyen (Bill308)

Member Username: Bill308 Post Number: 460 Registered: 5-2001 |

Ben, I think you're still a little high on the fuel pressure. Try 3 psi. | ||

| Ben Millermon (Brainsboy)

Member Username: Brainsboy Post Number: 272 Registered: 5-2001 |

Ok, I just installed a regulator and pressure gauge. The pump was putting out 6psi, so with the regulator I adjusted to 3.5psi and that fixed all the venturi's dripping, also it idles alot smoother. The only thing I havent been able to fix is the 3-4 carb from dripping at the accelerator pump nosel. I took it apart and cleaned it but still drips. | ||

| rich (Dino2400)

Junior Member Username: Dino2400 Post Number: 199 Registered: 10-2001 |

I would think that Pierce Manifolds would have the fuel inlet fittings that have an outlet for the return line. On my DCNFs it was 90degree but there are probably several styles. | ||

| Ben Millermon (Brainsboy)

Member Username: Brainsboy Post Number: 270 Registered: 5-2001 |

Thanks everyone, I will probably add the regulator and the return line, I have about 4 extra hoses from the tanks since it was a fuel injectioned car. | ||

| Steve Magnusson (91tr)

Intermediate Member Username: 91tr Post Number: 1731 Registered: 1-2001 |

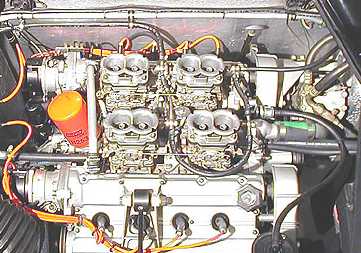

Here's a shot of the fuel line routing on a 308 GT4 (Peter R.'s car I think):  Fuel comes in from the line on the firewall and then passes by each carb's fuel inlet. The smaller line running to the right off of the 7/8 carb is the return line back to the RH side fuel tank. (The 1.5 mm diameter return restriction is built into the fitting the small line is hooked to, and the later 2v carbed 308s had a one-way check valve added to the return line too.) | ||

| Steve Magnusson (91tr)

Intermediate Member Username: 91tr Post Number: 1729 Registered: 1-2001 |

I think the return line is really a separate issue -- i.e., if you want a certain fuel inlet pressure you should make whatever design changes you need to achieve that inlet pressure whether or not you're running a return line. If you have an existing non-return line fuel system and add a return line, the inlet pressure will drop slightly, but it won't be huge (since the amount of return should be limited by an orifice -- the 308 specs show a 1.5 mm diameter return restriction). To drop the inlet pressure in half, you'll need to either use a pump with a lower nominal pressure output or add a regulator, but it would be a good idea to design the fuel system with a small return to prevent the gas in the lines from getting heated while waiting to be ingested. | ||

| Ben Millermon (Brainsboy)

Member Username: Brainsboy Post Number: 269 Registered: 5-2001 |

I do not have a return line, just a pure 6-7 psi direct line. Seems I have a few changes to make tonight. Anyone have photos of the fuel lines with webers? I didnt realize they had a return line. I guess I could just use a regulator without a return line. Im a little bit in the dark since my car is a GTSI. All my books are for the 81 fuel injection systems. | ||

| rich (Dino2400)

Junior Member Username: Dino2400 Post Number: 197 Registered: 10-2001 |

Having a return line from the carbs is a great idea if you don't have one. And I'll second the recommendation for lower pressure than the 6-7psi your pump may be providing. Webers really like low pressure, in the 3-4 range and I know people who use even lower. Though with the return line, I don't think pressure is as critical a factor. | ||

| DJParks (Djparks)

Junior Member Username: Djparks Post Number: 199 Registered: 2-2003 |

Steve brings up a good point. My 240 does NOT have a recirculating system where as my 308 does. If the floats are working properly it shouldn't make any difference in either case AT THE PROPER DESIGNED PRESSURE. With a non-recirculating system you have to rely on the fuel pump's internal bypass exclusively and this is where a regulator really comes into play. If the pump doesn't bypass until 7 PSI then you are over pressure on the carbs. It's my understanding that overpressure WILL affect float shut off at the proper time..(please correct me if I am wrong). | ||

| Steve Magnusson (91tr)

Intermediate Member Username: 91tr Post Number: 1728 Registered: 1-2001 |

Ben -- Just for reference the 308GT4 WSM shows the pump data as 4.3 +/- 0.7 psi (and the actual working pressure might even be lower if that doesn't include the calibrated "return hole") so I'd start in the 3~4 psi ballpark as DJ said. Not "leaking" with motor off doesn't necessarily indicate that the fuel level in the float bowl is OK (i.e., there's a fairly large vertical distance in the DCNFs between where the fuel level in the float bowl should be and where the level the fuel would need to rise to leak out with the motor off). Are you running a recirculating fuel layout? | ||

| DJParks (Djparks)

Junior Member Username: Djparks Post Number: 198 Registered: 2-2003 |

I bought an aftermarket fuel regulator and mounted it on the firewall just before the fuel line got to the carbs. I bought a regulator designed for street application because most of racing regulators wouldn't 'dial down' low enough for the Weber specs. Try JEGS or PAW. Even NAPA might have a unit worthy of a Ferrari. Go with quality for dependability. I have two 1972 240's ( I love these cars!). One I drive to work everyday. 2.5 liter, E88 head, balanced and blue printed with a Comp Cams 280 degree duration/110 degree lobe separation. Three Weber DCOE, side draft, two barrel carbs on a Cannon manifold. My other is an auto cross car with a Chevrolet 350, forged flat tops, Comp Cams 275 dual pattern, Trick Flow twisted wedge/2.02 heads, 650 CFM spread bore carb. Transmission is a Richmond 5 speed with 1:1 5th gear through 3.36 rear gear. I saw your 240 on the site. Looks like a SCREAM!..........Literally! If I can get my software to work I will try to post some pictures. It worked once but never again. Can't figure out why. I even read the instructions. I'll try to send on your personal E when I get home if you like. DJ | ||

| Ben Millermon (Brainsboy)

Member Username: Brainsboy Post Number: 268 Registered: 5-2001 |

DJparks, do you have a regulator on the fuelpump? holleys usualy put out 7psi. By the way what year 240 do you have? Did you see my 240 on my profile here? | ||

| Ben Millermon (Brainsboy)

Member Username: Brainsboy Post Number: 267 Registered: 5-2001 |

These are a 42dcnf. They are supposed to be the same design as the 40 and 44 webers. However these acutaly came off of a maserati. | ||

| DJParks (Djparks)

Junior Member Username: Djparks Post Number: 196 Registered: 2-2003 |

The book I have (Peterson?) covers DCOE, DCNF, IDF and references to others. I'll look it up when I get home. DJ | ||

| DJParks (Djparks)

Junior Member Username: Djparks Post Number: 195 Registered: 2-2003 |

Get the Weber book. Invaluable when rebuilding the three DCOE's on my 240. VERY specific on full open and full closed measurements for the floats. Included are diagrams and illustrations. They recommended 3 lbs fuel pressure for the carbs also. Since I am running 3 carbs I boosted the pressure 1/2 lb.. My fuel pump is a Holley rotory that is rated at 72 Gallons/hour, about 1.2 gallons per minute. I think that will feed well enough at 135 MPH. These carbs used to baffle me until I got this book. The first chapter actually explains why the carburetors are designed the way they are and how versitile they are when making adjustments and mods, mostly on the car too. DJ | ||

| "The Don" (Mlemus)

Advanced Member Username: Mlemus Post Number: 4266 Registered: 8-2002 |

Ben, You should have 40DCNF, not "42DCNF" Matt | ||

| Ben Millermon (Brainsboy)

Member Username: Brainsboy Post Number: 266 Registered: 5-2001 |

I knew you would say that as soon as I mention that. However the other carbs are working great and the carb leaking is now set with a lower fuel level. I was going to buy the book but wasnt sure if it had info on the 42DCNF. Anyhow thanks jrv for the info, I will play with it tonight and see. Ben | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1382 Registered: 11-2002 |

>>>Im not sure what the level is set too on the carbs because the photos I have been looking at are not very clear as to how << Ohhh Noooo buddy...that will never fly...:-( The float levels have specific height adjustment specs and procedures that must be adhered to. You are going to need either the carbed 308 WSM or one of the Weber Manuels to carry out setting and adjusting procedures. Order the Weber book from Pietce Manifolds when you order the "4" new Needles & Seats. | ||

| Ben Millermon (Brainsboy)

Member Username: Brainsboy Post Number: 265 Registered: 5-2001 |

Im not sure what the level is set too on the carbs because the photos I have been looking at are not very clear as to how to set them, but I have adjusted the carb with the venturi's leaking several times, if I adjust it any more there isnt going to be enough gas in the fuel bowls. Im assuming at this point it must be the needle and seat. By the way what kind of fuel pressure do you guys normaly run with webers? | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1380 Registered: 11-2002 |

What did you set float level to in MM's? One of the problems you describe sounds like FL Level too High/Stuck Needle & Seat... the other sounds like.....> There are 2 check Balls...1 is in the Carb Body in the Float Bowl in the brass plug capped tube in the left rear corner(acc pump side)...the second check ball is inside the Acc Squirters Pump Jet. | ||

| Ben Millermon (Brainsboy)

Member Username: Brainsboy Post Number: 263 Registered: 5-2001 |

JRV thanks, It must be the valve then since they all have new pumps. Where is the valve at inside the fuel bowl? | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1379 Registered: 11-2002 |

1- needs new Acc. Pump Diaphrams 2- Acc. Pump Anti-Siphin Valve stuck | ||

| Ben Millermon (Brainsboy)

Member Username: Brainsboy Post Number: 261 Registered: 5-2001 |

I have 4 webers that are giving me some trouble. When the car is not running and the electric pump builds pressure everything is fine. As soon as I start the car and let it idle, one carb leaks gas out the accelerator pump shooter, and anouther carb is leaking out the main venturi's. I adjusted the float levels with no luck. I am curious what kind of fuel pressure you guys run with your webers. I am using a holly red pump which I guess is probably 6-7 psi. I thought I might have too much fuel pressure but it doesnt leak with the car not running and the fuel pump on. Anyone have some suggestions? |