| Author | Message | ||

| Kurt White (Ferraribooks)

Junior Member Username: Ferraribooks Post Number: 91 Registered: 2-2002 |

Just an FYI, the BB clutch is the same as the 288 GTO, it's a twin disk setp & does come with the centre plate, $2200.00 for the entire kit. If you need one, drop me a line. Kurt 813-891-1817 www.ferraribooks.com | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 757 Registered: 8-2001 |

JRV: If the flywheel feels smooth, then can I just hand sand it. I recall somewhere, that you have mentioned 400 grit hand sanding of the flywheel. Is this correct? Tom: Things wear out. If the plate didn't break, it would have worn out fairly soon....it was VERY thin. If it wore out, I would have gouged the flywheel, probably......as a result I don't need a new flywheel because of the break. | ||

| TomD (Tifosi)

Advanced Member Username: Tifosi Post Number: 3763 Registered: 9-2001 |

great thread, sorry that this has led to a clutchetomy | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 755 Registered: 8-2001 |

JRV: Thanks for all your help. | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1603 Registered: 11-2002 |

OK original disc not rebuilt...guess that means you can dish out more than Ferrari clutches can take...;-) Kurt White @ Ferrari Books (sponsor) has BB clutches for $2200.00 which sounds pretty fair. | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 754 Registered: 8-2001 |

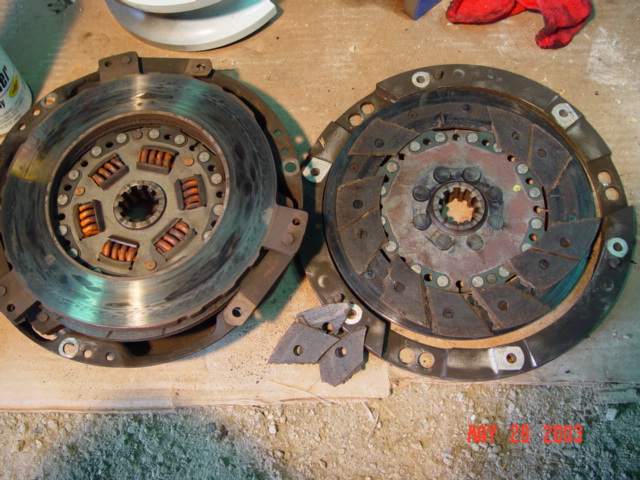

Not sure. There are 2 metal discs, each bearing the friction material on it's outside surface. There is also a "thin" metal "disc?" in between. It is not continuous in a circle.....it appears to be staggered. The first picture shows this, of the unbroken disc. It is thin enough to appear "wavy". | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1602 Registered: 11-2002 |

Henryk, how many metal plates sandwhiched between the disc friction surfaces (there should be 3)? any disc can disentergrate like you show here, but I've generally seen rebuilt discs come apart like that. | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 753 Registered: 8-2001 |

JRV: While removing the clutch assembly, the problem has shown itself: The surface material, on the inner disc, facing the intermediate ring, was all broken in pieces. They where still in place, so no metal to metal contact between the ring and disc. Now what? All metal surfaces appeared smooth to the touch......FW, interm ring, and PP. The first picture shows the thickness of the unbroken disc......about 1/4 inch thick.   | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 750 Registered: 8-2001 |

JRV: Thanks. I will get back to you tomorrow. Henryk | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1597 Registered: 11-2002 |

>>>what do you mean "....stand on the PP..."? << to test the fingers, fulcrum, spring action, the PP is layed flat and supported flat from underneath...then after placing something flat and round about the size of the TO bearing on top in the center, you stand on the center with one foot and apply enough wieght/pressure/force to move the fingers in and out to test the feel/action/strenght, unless you have a special PP tester with gauges of course...;-) | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 749 Registered: 8-2001 |

Pardon my ignorance, but what do you mean "....stand on the PP..."? I know that PP stands for pressure plate. | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1594 Registered: 11-2002 |

Looks like the clutch is rusty and guessing something stuck that one time you pushed it in. If the discs are fine and still maintain thickness within spec and intermediate plate and springs are ok, not cracked you might be able to oil/lube it all up and revive it... like noted below you'll have to stand on the PP and work it to determine whether it feels OK...if everything checks out and lubes up you can refit the bell housing and slave for a trial run. It will likely be a good idea to leave out the spacers for the next go around. | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 747 Registered: 8-2001 |

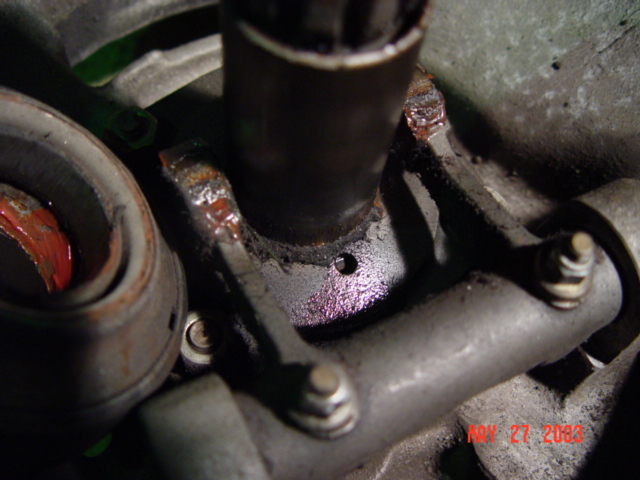

JRV: Here are closer pics. The contact area on the fingers are rusty.....yet the throw-out bearing runs fine......the car has been sitting for three days. BTW I am able to shift easily, into any gear, with the clutch cover off.....does this mean that it is not a trans problem? Before, I couldn't shift the trans, even with the clutch pedal pushed in......VERY difficult. I will remove the parts you mention, with labeling, tomorrow.   The fresh grease is from the "super" major service the car recieved about 1,000 miles ago. They checked the clutch assembly...OK...replaced clutch slave cylinder, and changed clutch fluid. All this happened Saturday night. Before then, the clutch worked fine. | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1593 Registered: 11-2002 |

Henryk, explain something, looks like fresh grease on the TO forks but the PP fingers look very rusty..is this what I'm seeing? Mark all the parts FlWh, PP, Intermidiate Plate and disassemble....mark the spacers (special washers) so you get them back in the right place (if they are reused)...let me know if the intermediate plate pins are still captured with the snap-rings.... hard to say on the fingers as to how far they protrude, not alot actually, as diaphragm PP's don't really travel alot to release...although parelell doesn't siund quite right..the fingers look rusty, if so they might have become stuck. You'll have to stand on it once off to check the action......but I'm thinking once disassembled you'll find something...like a failed intermediate plate. | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1590 Registered: 11-2002 |

Hold the pics closer to the monitor..I left my good glasses at work.... | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 746 Registered: 8-2001 |

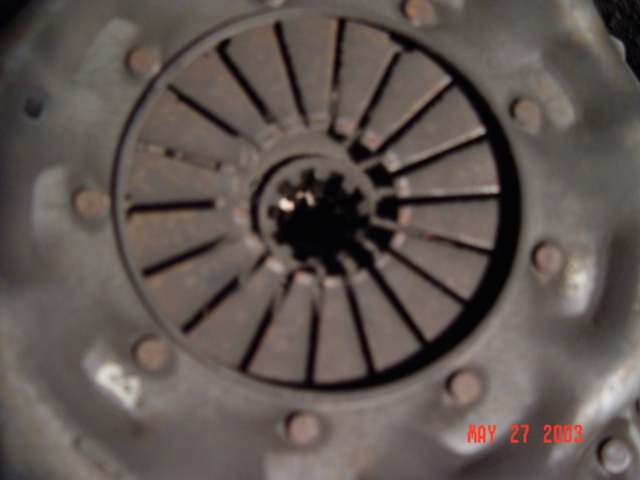

JRV: Sorry, but by the time I saw your post, I started taking off the two nuts....stupid, but I am learning a lot......I hope you still help me. BTW I removed the clutch housing....the hidden bolts where there....thanks. The forks and throw-out bearings are OK.....the center fingers of the clutch plate seem OK.....nothing broken. The only thing I notice is that the fingers are parallel with the flywheel....I thought they would stick out some....wrong? Here are a couple of photos:   I don't know where to go from here. I will do NOTHING until I hear from you, whenever. | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1584 Registered: 11-2002 |

Henryk, the nuts are left alone, the shaft on the bottom is splined insiside and slips/pulls out, the nut on the top gear holds the clutch shaft and stays in place. Once the Transfer Gears Housing in removed, pull the mainshaft and lay aside, then pull the bellhousing, leaving the upper shaft/gear in place. loosen all bellhousing bolts and carefully insure you get the hard to see fasteners on the bottom, once all fasteners are loose carefully pry/force the bellhousing off. | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 745 Registered: 8-2001 |

How about the smaller nut holding the top gear in? | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 744 Registered: 8-2001 |

So the gear housing comes off WITH the transmission shaft? | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1581 Registered: 11-2002 |

HOLLLLDDDD YEEERRR HORSES...;-) pull the entire transfer gear housing off, leave that nut alone. you don't have to pull that cover next time, you'll see once yoou get the TG housing off, then the bell housing | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 743 Registered: 8-2001 |

JRV: I disconnected the slave cylinder, and was able to move the rod by hand about 1 inch. I removed what you recommended......then I removed the small square cover over the transmission shaft......stopped, due to the 4-square holed nut. It seems that I will have to machine a wrench for this. Any EASY way to remove it? | ||

| Dr. I. M. Ibrahim (Coachi)

Member Username: Coachi Post Number: 275 Registered: 5-2002 |

This may be totally unrelated, but I once had an interesting problem with my Boxer clutch. It got stuck as in rusted and stuck. It was in gear. I bumped it back and forth a few times and the clutch released...I then remembered to engage the clutch if I was not going to be using the car for a while to keep it from rusting stuck. I used a 2x 4 too.. | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1576 Registered: 11-2002 |

Henryk, yes it is a good idea to carefully double check the external parts of the system for proper operation & condition, hard to say not being there, but it's possible it's something on the outside. | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1575 Registered: 11-2002 |

Just rear valance, center muffler (is so equipped),aluminum heat shield, air cleaner intakes, misc, then bell housing..and you're there. | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 740 Registered: 8-2001 |

JRV: I hope that you aren't planning on leaving FerrariChat in the near future...... Thanks again. I will keep you informed. | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 739 Registered: 8-2001 |

JRV: I will first try to move the shaft by hand per your recommendation, prior to removing the exhaust. The car is already on the lift. | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 738 Registered: 8-2001 |

Thanks for the tip, JRV. Not having someone here, I ended up using a long 2X4 to depress the clutch......there is movement at the housing, about an inch. Due to the fact that the pedal feels soft, and the linkages are intact, I will assume the problem to be within the clutch. I will proceed to remove the mufflers. I am assuming that the engine does not have to be removed from the car. | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1573 Registered: 11-2002 |

First thing to check is rear arm travel distance and visual movement of the external parts of the system...would require two people, one to push & release peddle, the other to carefully view and asses movement of the external parts....if everything on the outside appears to have full range of movement, perform one last check before the bell housing would need to come off, and that is remove the clutch slave and arm and check freeplay and resistance/movement of the TO cross shaft itself, of course you should not be able to move against the PP with only hand pressure...if you can move the cross shaft by hand or minor leverage, then the problem would be broken TO fork or collasped PP imo. tip: to pull the clutch slave, double nut the monting holder studs and remove them, slave & mount pulls right out of the way without removing fluid line. | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 737 Registered: 8-2001 |

While driving the Boxer last night the clutch appeared to go out. Pedal was VERY loose, unable to shift.....nursed it home in 3rd gear. I thought it was a linkage disconnect, at first....being that the system is hydraulic. Today I checked it: linkages OK beneath the dash, and at the clutch housing; pushing the pedal results in movement of the linkage at the housing; pedal movement still loose; able to engage 3rd and 5th gears, while engaging the clutch, but not easy; while in 3rd, letting out the clutch, the car will move forward; unable to engage 1,2,or 4th gears......possible but it appears to be very hard......don't want to break more. Any opinions.....JRV,etc.??????? Thanks |