| Author | Message | ||

| Verell Boaen (Verell)

Member Username: Verell Post Number: 957 Registered: 5-2001 |

Paul, There are several alternatives: 1) notepaper: Re-read Dave Helms post #82 below, and my post #935. Dave's a long-term Ferrari dealer mechanic. He made it clear that for keeping the cams from rotating while aligning the cam gears: There's no problem with using a strip of notebook paper, 1-layer thick if a low mileage car, at most doubled over if a high mileage car. Only tighten the cam cap enough to keep the cam from rotating. This is generally finger tight or a little more. 2) A pair of vice grips with heavily masking taped teeth, clamp 1/cam with their handles crossed. Align cams & duct tape the handles together to preserve the alignment. 3) Make a pair of wrenches that pick up the hexagonal flats on the cams (between the seals & pulley mounting flanges) out of ~1/8" thick flat stock. Cross them & tape them together, or cut slots in them so you can use a thumbnut & carriage bolt. If you know that the cam gears are properly pinned, (They will be after you do your 1st major service) Then use one of the following to lock the cam gears in place while replacing the belts: 1) Baum Tools, Snap-On & others sell a tool that clamps onto the cam gears & holds them in place. (read $$$.$$) 3) Make your own tool: a) a piece of 3/16" to 1/4" thick 1" wide steel with a strip of belt cemented onto it. It needs to be about 2" longer than the center-center distance between the cams. Drill a ~1/4" hole centered both side-side & end-end of the strip. b) A wooden block: Cut a piece of wood into a ~1" high truncated triangle that fits narrow end down between the cam gears. Narrow end must fit above their centerline, the wide end must be about 1/2" but below the bottom of the belt. Drill a 1/4" hole down thru the wood block. c) bolt, washer & wing nut: Run a long thin carriage bolt down thru the block, between the pulleys, thru the hole in the metal strip. Put a washer & wing nut on it. When the wing nut is tightened, the block wedges between the upper edges of the cam gears, & the strip of belt aligns the gears exactly the way a belt would. The block doesn't have teeth, so the gears can turn slightly on it as necessary to ensure the belt strip aligns the gears. The bolt only needs to be tight enough to ensure that the gears can't jump a tooth on the belt strip, and that the block won't slip out. You can slide the strip side to side to rotate the gears slightly to exactly align the marks, or to let the belt slip on. The only tight requirement is that the metal strip with the belt must be flat between the points where the belt teeth engage the cam gears. Alt #3 just hit me as I was writing this post. I've been trying to figure out a simple, flexable 3x8 cam alignment tool tool for quite some time. This sure looks like it does the job & is simple to make! Just remember that the plastic gears are fragile & don't tighten the bolt enough to crush them. | ||

| Paul Jeffery (Peajay)

Junior Member Username: Peajay Post Number: 85 Registered: 4-2002 |

I totally agree with the comments made about not expecting paper/card or whatever under the cam caps to counter-torque the pulley bolts (engine in gear and handbrake on will do that) but what is the recommended method for preventing cams from rotating when the belt is removed ? From my own brief experience on a 328 I know this happens quite easily on the front bank. There is not enough room to clamp the cam forging behind the pullies, so what works if not using the cap locking ???? | ||

| Verell Boaen (Verell)

Member Username: Verell Post Number: 951 Registered: 5-2001 |

Dave, Thanks for the response. The o-ring does get quite deformed. I once replaced a truly ancient one that was so hard it held its shape after I broke it off of the seal housing. Cut a cross-section. About 2/3 of the 'diameter' on all 4 sides was flat from being compressed by the groove's top,bottom, & sides! Learned that punch 'stakeing trick' from an old-time jaguar racing mechanic back in college. It's served me well over the years. Also learned the hard way to never use RTV to retain a seal. It's far too slippery while uncured, like expecting grease to hold something! Loctite 515 & 518 anaerobic sealants are made for retaining rubber shelled seals in metal housings. They do a great job & cure up quite fast. Of course, if the housing is in good condition, &properly cleaned, the seal's shell should be sufficient to retain the seal & ensure no leaks around the housing. | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1932 Registered: 11-2002 |

>> When the 308GT4 was new, there was a great deal of problems with the seal slipping, or poping out.<, Right, I've never heard an explanation, but by simply following the evolution of the design and evolution of the parts used, it looks like leaking and longivity was the issue being resolved. Yea short cuts, sure, the real short cuts are mental = get over being lazy, and just accept that doing it right is work, and you will have found the best short cut of all. Knowledge is King - Trix are for Kids. | ||

| Dave Helms (Davehelms)

Junior Member Username: Davehelms Post Number: 83 Registered: 5-2003 |

Verell, No explanation I have ever heard of. When the 308GT4 was new, there was a great deal of problems with the seal slipping, or poping out. The more sealant that was used, the worse the problem got. Now take any thickness differances in the gasket, or addition of sealant to the gasket, and the nip of the seal has totally changed. This is why so many of the early 308's have stake marks from a punch all the way around the seal seating area. It was to create a "grab" on the seal to keep it from slipping out. The QV oring method has a fair amount of flexibilty in how much the oring is "nipped". I suspect that is why the groove is square cut, and the oring round. To allow extra deflection of the oring in cases where there is more of a nip. Expansion and gaskets thickness differances are taken up with how much the oring is crushed. Mitchell, I am having a hard time picturing what you are suggesting, but I think you are saying the matchbook is between the head and the cam. This would require all of the journals to be loosened quite a bit, and if you are that close to the cam removal it isnt a short cut. No reason to battle the seal in those close quarters when with the cams out you can slip it right off in less time. Matchbook above or below still equals 10#s of S--t in a 5# bag. Torque it to spec and it has to go some where. It still wouldnt hold the cam against break away using a ratchet, if the bolts were torqued properly the first time around. | ||

| Bill White (Nc_newbie)

Junior Member Username: Nc_newbie Post Number: 139 Registered: 2-2003 |

The wedge (match book or folded paper) method scared me. I would never attempt that. I broke a cam cap years ago on a tractor (not a Labo but a MF) just by not torquing them equally. I got in a lot of trouble with my dad for it. Thanks again F-Chat...Job almost done, one more cam cover, dist. and cam end cap on the front bank and I am done... Bill | ||

| Mitchell Le (Yelcab1)

Member Username: Yelcab1 Post Number: 591 Registered: 11-2001 |

Have you considered that a "match-book cover" fit underneath the concave part AND the flat part of the cam-cap would not bend or break the cam cap when torqued to spec? And still provide enough crush friction to hold the cam steady? If one or two caps treated this way does not hold the shaft enough to remove the bolt, then you remove the camshaft, or use a strap wrench. It is called a short cut! But enough about this bickering. To each his own. | ||

| Verell Boaen (Verell)

Member Username: Verell Post Number: 943 Registered: 5-2001 |

Dave, Thanx, Somehow the 'torque to spec' hadn't registered when I read that post. ANOTHWR Q: I've always wondered why the O-ring/seal housing setup was used for the qv & 348 engines rathar than the way the 2V cam seals mounted. My best guess was that it was needed to let the seal float into concentric alignment with the mating cam surface. Did you ever come across a factory explanation? | ||

| Dave Helms (Davehelms)

Junior Member Username: Davehelms Post Number: 82 Registered: 5-2003 |

Verell, thanks. My reply was in reaction to Mitchell's statement "put a match book cover under the one or 2 of the cam caps, torque to spec". If the engine is any shape at all, there is only .003-.004" of clearance, and trying to put a piece of cardboard that is in the order of .015" in that space, and then torquing to spec is the most likely reason for the failures I have been running into. As stated earlier, note book paper, folded over if the engine is worn, has been used since long before I was taught how to service these cars, with no problems I have ever heard of. But note paper is on the order of .004" thick. The problems I am currently dealing with were caused by a dealer tech as well. There is some unbelieveable talent within the dealer network, and I can say this first hand as I have been in the same classes both in NJ and at the factory with these guys. But with any profession, there are bad ones as well. The cut o ring is simply a way to remove the seal holder with out taking the cams out. Remove the cam pulley, cut the oring and slide the holder off. Cut the new oring and wind it around and glue the ends together. Biggest bunch of hack work I have ever watched! This type of fix was done to the 348's under warranty when the gasket cut the oring, but that was justified as it saved 37 hrs, and the seal was in fine shape (read new) anyway. On these cars (3-8) there is no way to justify that type of work. Mitchell "Of course, JRV and the other master mechanics may think that this is all "crap" anyway" Nope, just some of the ideas I have written about, and gave reasons for. But my appologies for my rudeness earlier stands. | ||

| david b holmes (Mondial86)

New member Username: Mondial86 Post Number: 6 Registered: 7-2003 |

Ask questions ,to educate yourself,arm yourself with as much infomation as you can ,then start or,finish Your project ,but do it right !People like JRV are so important becaus they are educated,and are armed with such a wealth of imformation,who cares about there bedsid manor.wee need there knolage. | ||

| Verell Boaen (Verell)

Member Username: Verell Post Number: 941 Registered: 5-2001 |

Bill, You're right, cam caps are the same specs as the cam cover 6x1s. In general Ferrari uses the same torque spec for all bolts or nuts with the same diameter & pitch. Good idea to always check tho. Only when you get to the large/unique things like the various ring nuts, cam gear bolts, vibration damper bolt can you expect the spec to be situation specific. | ||

| Eugene Angelo (Eangelo)

New member Username: Eangelo Post Number: 46 Registered: 8-2001 |

Even though JRV can be difficult at times, you've got to admit he's got a sense of humor!!! He cracks me up sometimes!!!! BTW, JRV - I ordered some new Pirelli tires. Eugene | ||

| Mike Laws (Mikelaw)

New member Username: Mikelaw Post Number: 4 Registered: 7-2003 |

There goes JRV spouting more of his negative crap! To be honest he knows so much more than most and can help so many that it's a shame to see him going on like this!!!!!!!!!!!!!!!!!!!!! | ||

| Kelly (Tifosi1)

Member Username: Tifosi1 Post Number: 698 Registered: 2-2002 |

And everyone is always saying the 2 V are slloowww. Thanks Verell I never noticed. Kelly | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1927 Registered: 11-2002 |

>>Of course, JRV and the other master mechanics may think that this is all "crap" anyway.<< No skin off my nose, in fact I simply see the next gen of parts cars in the making. Attrition is a great way to keep the values of the ones left up, and with a ready supply of used parts, it'll be a win win. ;-) | ||

| Mitchell Le (Yelcab1)

Member Username: Yelcab1 Post Number: 590 Registered: 11-2001 |

6-7 lbs is more than enough. remember there are 10 of those to a cam shaft. My 2V engine calls for 9-10 Newton Meters. Of course, JRV and the other master mechanics may think that this is all "crap" anyway. | ||

| Bill White (Nc_newbie)

Junior Member Username: Nc_newbie Post Number: 137 Registered: 2-2003 |

Just checked the QV workshop manual and they do not list a torque spec for the cam caps? What do your guys recomend? I see that the cam covers recomend 0.9kg/m for the 6.0x1.0 bolt which is what the cam cap is also. This is only about 6-7 ft/lbs which seems to me like the torque of the cam caps should be more like 15-20ft/lbs. Thanks, Bill | ||

| Verell Boaen (Verell)

Member Username: Verell Post Number: 940 Registered: 5-2001 |

Kelley, Bill has a qv engine. That nice `1" gap between the head & the cam gear on the 2V engine is taken up by the circular cam seal housing, leaving about a 1/4" gap on a QV engine. Also, the qv cams doesn't have that nice hex! | ||

| Kelly (Tifosi1)

Member Username: Tifosi1 Post Number: 697 Registered: 2-2002 |

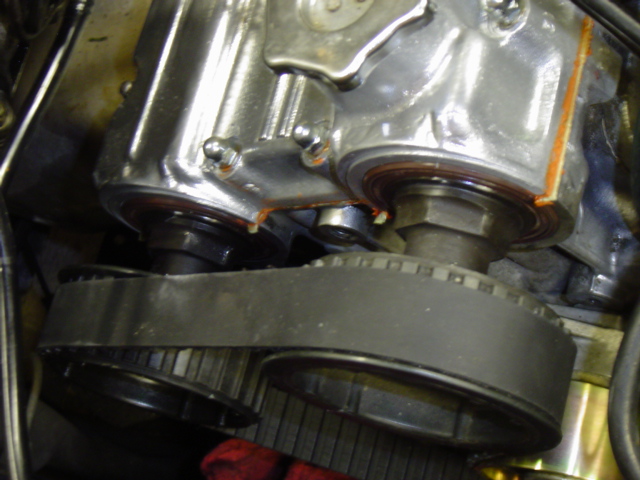

picture of where to use a crescent wrench on th cam  | ||

| Frank Parker (Parkerfe)

Advanced Member Username: Parkerfe Post Number: 2685 Registered: 9-2001 |

I know its low tech, and not the "right" way to do it, but when I had a leaking cam seal in my 348 I used a bottle of a sealer I bought at PepBoys and it worked. Even 3k miles later when I traded the car for my Boxer the cam seal was not leaking. | ||

| Mike Laws (Mikelaw)

New member Username: Mikelaw Post Number: 3 Registered: 7-2003 |

Bill, I wouldn't worry about it. It seems that JRV has these fits on occasion. I remember one between Frank P and JRV that went on and on. | ||

| Kelly (Tifosi1)

Member Username: Tifosi1 Post Number: 695 Registered: 2-2002 |

I took the cams out of the car, used a 12inch crescent wrench to hold them and used a breaker bar to brake the nut. Don;t for get to bend back the lock washer. Kelly | ||

| Bill White (Nc_newbie)

Junior Member Username: Nc_newbie Post Number: 136 Registered: 2-2003 |

Thanks to all for the help ... Front bank ready to torque cam caps... One last comment to JRV then I'll let the thread fall to the archives with no more responses from me.... I did back away immediately and then posted on F-chat (good advise Tom even though that was what I had already done) and I would not have even approched this method had a "Ferrari mechanic" not suggested it in the first place. I did do a valve adjustment last time I replaced the seals. The only reason I am doing it again is because a distributor seal and a cam seal has started leaking again. After a couple of hundred miles. I now know why. JRV, I find it interesting that you jump to try to insult me. I guess the intent is to make yourself feel smarter. Anyway at this point I am not insulted. I do have dial gauges for setting cam overlap on porsches but no reason to use them on a ferrari since it is easy enough to line up the indexing marks. I don't need to defend my procedural knowledge or intellect to you. I'll be glad to go into my years as a mechanic or graduate school degrees in engineering if you want to take it off line. You could be much more informative and less offensive on this board and it may even help your business and gain you more respect. When it requires some sort of formal education to work on Ferrari's like it does Turbine engines I'll leave it to the professionals. Otherwise these things are not that difficult. Bill | ||

| TomD (Tifosi)

Advanced Member Username: Tifosi Post Number: 4128 Registered: 9-2001 |

"Even TomD read your methodology and felt compelled to suggest you back away " Should I feel insulted  | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1925 Registered: 11-2002 |

Bill, Even TomD read your methodology and felt compelled to suggest you back away from the car before you created more problems than you were trying to solve. To be blunt and honest, you should have replaced the seals AND o-rings in the first place when you were installing the new belts! And now that the covers are off isn't a valve adjust appropriate? Is the engine out of the car like it's supposed to be for this list of procedures? Sorry but what you lack in procedural knowledge could fill volumes. IMO, they way you are going about "improving" your Ferrari engine has all the tale tell signs of working against a quality completion, like re-using used belts for example. And additionally Dave is correct about the Match Book and not that long ago someone right here posted of busting a cap in half! Do you posses the "Cam Timing Tool" to aid is setting the cams correctly to avoid bent valves on start up? Would I win if I bet No? | ||

| Verell Boaen (Verell)

Member Username: Verell Post Number: 938 Registered: 5-2001 |

Mitchell, Wow! Never encountered that problem. The belt has always held for me while torqueing the cam gear bolts to spec. I always delay torqueing the cam gear bolts to full spec until the very last step before installing the cam covers. ie: After cam gear alignment has been verified by multiple engine rotations, & the tensioner bolts have been torqued down. (Well, the 1st time I did 308 cam seals, I didnt delay, & sure 'nuff I had to pull the bolt to fine tune alignment by re-pinning the gear.) | ||

| Walt Pfirman (Waltp)

Junior Member Username: Waltp Post Number: 55 Registered: 7-2002 |

Bill, WAY TO GO !!!! Glad to hear that all is going well with the seal replacement. I also give thanks to all that have helped me here at FChat. | ||

| Bill White (Nc_newbie)

Junior Member Username: Nc_newbie Post Number: 135 Registered: 2-2003 |

JRV, I am slightly offended by your comment. I don't feel the I "jumped off a bridge" taking on the project. Maybe you meant that I "could" have made a mistake if it were not for the advise from Ferrari chat. Rear bank complete now starting front bank... did not have to remove the pulleys since I removed the cams. It would never of worked without removing the cams! Thanks to all, Bill | ||

| Mitchell Le (Yelcab1)

Member Username: Yelcab1 Post Number: 589 Registered: 11-2001 |

Bill When I did mine, all four cam shafts were already off the car, so putting it in a bench vise, and using an air-wrench was the way to go. That said, during installation of the belts, I did have to move the pulley to adjust the fine eccentric holes for lining up the belts. Again, the air wrench did remove the bolt. For tightening it, the belt and the tension alone did not hold the pulley stationary to withstand a 78lbft of torque (even when the crankshaft was held steady by someone else with a ratchet). We finally had to hold the cam pulley with a big-ass plumber's wrench with some protection for the teeth. So, in effect, it was a strap wrench method that we used. | ||

| Mitchell Le (Yelcab1)

Member Username: Yelcab1 Post Number: 588 Registered: 11-2001 |

Quote: Do it like I do...let it out, the frustration of all the years of hearing BS...just post the truth and if some can't take the truth and reality then, #1- they need to grow up or get a therapist or both, #2- they have no business working on cars, let alone Ferraris End of quote. Wow, if ... letting it all out includes recent examples of someone calling someone else "... inbred hillbillies..." then, here's to hoping for more civility than that on Fchat. | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1922 Registered: 11-2002 |

>>Where does this crap come from JRV?<< I think from drinking bad water...must be? Dave, I've read and enjoyed your posts and still after all my years try to follow the Golden Rule of Learning Something Real & Valueable Every Day. So Please continue posting in your own style, with your own emotions and knowledge. Do it like I do...let it out, the frustration of all the years of hearing BS...just post the truth and if some can't take the truth and reality then, #1- they need to grow up or get a therapist or both, #2- they have no business working on cars, let alone Ferraris Believe me I understand how you feel when reading some of these dangerous "tricks" and other total baloney stories...hell it's mild now compared to when I first joined..;-)....it used to be neck deep...now a good pair of hip waders will do. Lastly, this thread should serve as a perfect example of why you are needed here to help some of these guys who blindly jump of bridges..never considering below awaits a dry creek bed. | ||

| Verell Boaen (Verell)

Member Username: Verell Post Number: 935 Registered: 5-2001 |

Dave, Aplolgy accepted. Anyone can have a bad day. I'm sure your years of Ferrari experience will be a great asset to the F*Chat. Can you clarify just a bit exactly what you were referring to when you say 'quick fix'. ie: The cut o-ring & it's consequences? I spent about 40 or 50 hours undoing the 'quick' fixes the dealer's mechanic used on my 308 engine. Including un-doing some of them because they looked reasonablle when I found them: (ie: RTV in the cam seal housing o-ring groove). The hack I couldn't believe was when I found that he'd removed & re-installed the timing drive gear ring-nuts using an air chisel & punch(photos in the archives)!!! Also, I'd appreciate your opinion on the following: I've always considered the 'paper under a journal' as a useful technique to keep the cams in place while aligning the cam gears & installing the belt. Doing this does not require seriously tightening the journal. Finger-tight, or just slightly more on the cap's nuts has generally sufficient. This use is where the 'matchbook' cover trick was originally recommended. However, using paper under a cam cap to lock a cam against the break-away torque of the cam gear bolts is another thing altogether. The break-away torque for these bolts must be on the order of 100-150 ft-lbs! Trying to resist that amount of torque using a piece of paper about 1/2" away from the cam's centerline just doesn't make sense!!! I can see how torqueing the cam cap tight enough to resist this force would bend or break the cap! | ||

| Dave Helms (Davehelms)

Junior Member Username: Davehelms Post Number: 81 Registered: 5-2003 |

Verell, As with every reply that I have read that you posted, you are right again. I was out of line, completely! The first Ferrari I serviced was back in 72, and I have been doing it ever since, and having to listen to how expensive they are to maintain, and how un-reliable they are. For the last few days I have been playing janitor to someone that hacked up a beautiful 328, and taking the brunt of the comments from the owner regarding how expensive the repairs are. All his problems came about because of a "few quick fixes" that were done rather than doing right once. My appologies to all offended, it was not my intent, just frustration showing through. One of the reasons I left the dealer network was just this. Customers expect their $200k car to be fixed correctly, and trust that it will be done, yet there is a bean counter making all the decissions on how "well" it is done. Real world economics I guess. At least now I know why I am starting to find so many cam caps that have to be pryed off the studs and straightened in the press. The reason for this has eluded me up until now. This 328 that I am doing now had to have the cams smacked with a plastic hammer to remove the front caps on 3 of the 4 cams. I suppose it was the same person that cut the oring so the seal holder could be removed with the cam in place. The resulting oil leak filled the alt. with oil, so that was replaced (by another auth. dealer, have you ever priced one of those from a dealer?). The time it takes to straighten caps, re-ream the journals, and clean up the filings is the cost of that "quick fix" It takes 20 mins to do the job properly the first time when you are there, and somewhere around 45 hours to fix it in this case. With so many of the posts talking about what a rip off Ferrari techs are, the heat I had to take at the shop about this job and the fact my A/C didnt work on the way home, that lead me to reply in a non-prof. manner. Sorry. | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1919 Registered: 11-2002 |

>> Take out the cams with pulleys attached << Only way the job can be done, "properly". And before you find out what happens to belts that are used twice the hard way, to the tune of $8K, I'd buy 2 new belts if it was my "Ferrari" engine. | ||

| Verell Boaen (Verell)

Member Username: Verell Post Number: 931 Registered: 5-2001 |

Bill, You'r right, compression is far too light to resist the torque needed to break the cam gear bolts loose. Put the tranny in 5th gear & lock the parking brake hard. THE BELT TENSIONERS MUST BE TIGHT IN ORDER TO DO THIS. DO NOT LOOSTEN THEM. Make sure the flywheel is on the PM1-4 mark. If you've got a 1/2" drive impact wrench, use it to break the cam gear bolts loose. Otherwise it'll take a 1/2"inch drive breaker bar. Either will work with the drive train keeping the engine from turning. The folowing thread has quite a few tips on changing cam belts: http://www.ferrarichat.com/discus/messages/256120/107771.html With a QV engine, you're right, you have to pull the cam to replace the O-ring that retains the seal housing. If you have'nt read this thread, I highly recommend it: http://www.ferrarichat.com/discus/messages/256120/65844.html This thread precedes the above one & has some good tips, but READ IT CAREFULLY as experience was being acquired the hard way as the thread progressed: http://www.ferrarichat.com/discus/messages/256120/65756.html ie: Some of the suggestions I gave early in this thread were found to be bad ideas by the end of the thread. Dave, Since your opinion of this site is so low, why don't you just take your low opinions & go somewhere else. Sarcasm and insults may have a place somewhere, but not this topic. We try to keep the Tech Q&A topic on a courteous professional basis, even when we are disagreeing. MATCHBOOK TIP'S HISTORY: It was only last August,in the 1st thread I referenced above, that James Selvan identified the risk of a matchbook cover possibly breaking a cam cap. Historicly There've been a lot of people that have used a matchbook cover successfully. That particular tip goes back at least 5 years or more. I first found people discussing it in the FerrariList archives in eMAIL dated long before the FerrariChat was started. Ric Rainbolt was one of them. He later used it in his write-up. Don't know who first suggested it tho. I understand then that it originally came from a long-term Ferrari mechanic. I've also encountered it on several other Ferrari web sites. Based on what I read back then, I've successfully used it a couple of times myself, and also twice have successfully used an even thicker piece of cardboard cut out of a cam pulley box. However, I believe many of the members are now aware that they should be using something thiner like a 1" piece of busness or playing card, or a double-folded sheet of paper (or a $100 bill if you're feeling rich.)I do have to confess forgetting it in a post I made last month, but I did mention that using a matchbook cover was 'risky'. BTW, To the best of my knowledge, no one has actually reported breaking a cam cap while using a matchbook cover. | ||

| Jeff Green (Carguy)

Member Username: Carguy Post Number: 365 Registered: 10-2002 |

DAVE is correct! I too fell into the "matchbook cover" method, but have since been educated by experienced people. A piece of paper, at most folded once, is enough to hold cams in place. Spread the word! | ||

| Henryk (Henryk)

Member Username: Henryk Post Number: 908 Registered: 8-2001 |

Bill: I replaced cam seal on a 328......the one where the distributor is at. You will need a "special" tool to get it in properly.....without this tool you will fail. Been there......done that! | ||

| Mike Laws (Mikelaw)

New member Username: Mikelaw Post Number: 2 Registered: 7-2003 |

Dave, the match book cover item comes from Ric Rainbolt at ExpensiveCar.com | ||

| Mike Laws (Mikelaw)

New member Username: Mikelaw Post Number: 1 Registered: 7-2003 |

I'm with WaltP!! Take the cams out and change them that way!!!!!!!!!!!!! I hear a lot of opnions of who to listen to but no real help! | ||

| Dave Helms (Davehelms)

Junior Member Username: Davehelms Post Number: 80 Registered: 5-2003 |

Where the hell did this match book cover thing come from?! A piece of note book paper locks cams, a match book splits the caps into multiple pieces! How much clearance do think there is there? Im starting to read so much bad advice on this site, Im starting to read it only when I need a good giggle! Im with JRV all the way on this one, follow TomD's advice to the letter. Where does this crap come from JRV? | ||

| Bill White (Nc_newbie)

Junior Member Username: Nc_newbie Post Number: 133 Registered: 2-2003 |

I've got it now. The "local" ferrari mechanic told me I did not have to pull the cams but could just remove the pulleys to change those seals. If there is a grove for the cam seal housing O-ring then the cams have to come out. So I'm going to pull the cams. Thanks to everyone for all of the help. The only regret is that this is now the second time I'm doing this the last six months because a leak developed after the last time. I think I deformed an edge of a seal putting it in the first time.... live and learn | ||

| Andrew A. Illes (Andyilles)

Junior Member Username: Andyilles Post Number: 159 Registered: 10-2002 |

Bill.. Yes, you have to loosen the caps to get the seals out anyway... so just take the cams out. Then, just clamp them in a vise (with protection) to get the pulley nuts off. The MOST important thing is to make SURE you're at TDC first (all marks line up), and don't move anything, so you can put everything back without changing the cam timing. Alternately, the "shade tree" method. You can loosen the caps just enough to get the seal out, and lock the cam against rotating with vise grips (with a rag to not mar the cams) to get the bolts out/torqued back on. Don't forget to replace the O-rings under the bolts either. Good luck, Andy | ||

| david b holmes (Mondial86)

New member Username: Mondial86 Post Number: 4 Registered: 7-2003 |

Behind yhe pullie there are flat spots in the cam ,if you can find a rench to hold those flat spots you can remove the bolts.To put it all back together you will need to loosen the caps to let the cam come up a bit so that the big o ring on the cam seal carier will slip back in its groov in the head with out beeing damaged. So pull the cams out and check all the caps for wear.itis not that much work. | ||

| Bill White (Nc_newbie)

Junior Member Username: Nc_newbie Post Number: 132 Registered: 2-2003 |

JRV, et. al. What do you recomend... Take out the cams with pulleys attached or come up with a way to lock down the cams to remove the bolts. Since I understand you have to remove the cam caps all sequentially with a small amount of turns on each it is just as easy to remove the cams as it is to lock them down using the match book cover method (i.e. since you can not remove just one cap). Bill | ||

| JRV (Jrvall)

Intermediate Member Username: Jrvall Post Number: 1914 Registered: 11-2002 |

>>me thinks you should stop right where you are and wait for the techies to come along<< Ha Ha Ha... Now that's some damn solid advice that he would do well to heed!! ;-) | ||

| Mitchell Le (Yelcab1)

Member Username: Yelcab1 Post Number: 584 Registered: 11-2001 |

1. Strap wrench may work 2. Or, put a match book cover under the one or 2 of the cam caps, torque to spec, now the shaft will stay in one place while you remove the big bolt and pulley. | ||

| Walt Pfirman (Waltp)

Junior Member Username: Waltp Post Number: 54 Registered: 7-2002 |

Bill, I don't have much mechanical experience with Ferraris yet but (and I'll probably catch heck for suggesting this) it looks as if it would be simpler to align all the proper timing marks then remove the cams 1 at a time, and slide the seals off and then back on from the other end (at least on my 308). It seems much easier and I'm sure I'll now find out if there are any reasons not to go about it in this way. | ||

| Bill White (Nc_newbie)

Junior Member Username: Nc_newbie Post Number: 131 Registered: 2-2003 |

Actually I am not planning on putting new belts on because these are only a month/200 miles old. I did stop when I saw the engine was turning. I also was thinking that I could put a small block between the pulley to lock them in place without putting any real pressure then on the belts. Bill | ||

| Craig Dewey (Craigfl)

Member Username: Craigfl Post Number: 641 Registered: 1-2001 |

You need to be careful about turning the engine with the cam pulley. If you jump a few cogs, you could get interference and bend a valve. You will be putting new belts on after this anyway.... I would try a "strap wrench" wrapped around (and over ) the cam belt, disconnected so it can't turn the engine. Extra retarding torque can be had by putting a socket on the bolt opposite you are trying to loosen. Carefully... | ||

| TomD (Tifosi)

Advanced Member Username: Tifosi Post Number: 4107 Registered: 9-2001 |

me thinks you should stop right where you are and wait for the techies to come along  | ||

| Bill White (Nc_newbie)

Junior Member Username: Nc_newbie Post Number: 130 Registered: 2-2003 |

OK I am trying to get the cam pullies off so I can replace the cam seals. I know the torque specs are 78ft-lbs. I can not break the bolts loose because the engine keeps turning. I left the belts on with tensioner thinking that would allow me to get the bolts out. But the compression alone will not let me break them loose. I am also concerned that this method may damage the belts. So how do you lock down the cams to get these bolts out safely? Thanks, Bill |