| Author | Message | ||

| Ric Rainbolt (Ricrain)

Member Username: Ricrain Post Number: 537 Registered: 2-2002 |

Could you have weak motor mounts? | ||

| Mark Collins (Markcollins)

Member Username: Markcollins Post Number: 288 Registered: 7-2002 |

Jeremy Mine failed a few years ago and I was told it is a common problem. The cost of a replacement in the UK was about �70 UKP so not too expensive | ||

| dave handa (Davehanda)

Intermediate Member Username: Davehanda Post Number: 1310 Registered: 5-2001 |

If the lines are braided stainless, would you suspect the lines are too short, and putting too much "pre-load" on them? Would making the lines a bit longer help? Or use a mount that has a bit more "flex or give" in it? | ||

| '75 308 GT4 (Peter)

Advanced Member Username: Peter Post Number: 2930 Registered: 12-2000 |

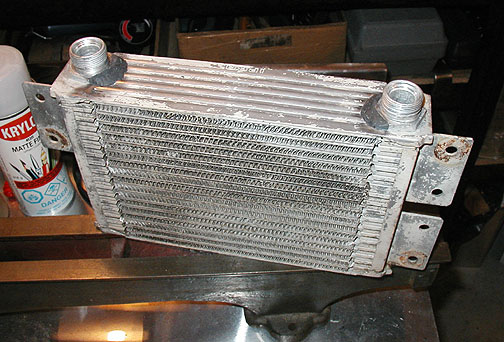

I forgot to add, I said that one fitting was leaking, but in the picture you can see I "fixed" both. I figured that if one blew, the other would probably be not far behind in going as well. Preventitive maintenance!  | ||

| '75 308 GT4 (Peter)

Advanced Member Username: Peter Post Number: 2929 Registered: 12-2000 |

I'm not sure Steve. What I can say is maybe poor design. My cooler sprang a leak last month. Just like Jeremy, it was the lower fitting. The fittings look like they're brazed on and I don't have a problem with that, but what I don't like is they placed it at the edge of the reinforcing ribs on the body. I suspect there's little amount of brazing to hold it in place in those areas and the constant vibrations and heat/cooling cycles just split it open (remember, there's lots of pressure circulating through there). It was a pinhole-sized leak, but enough to drop a litre of oil after every drive! My fix was to lump some JB Weld on there, since brazing/welding would've been too difficult. So far, its holding fine. If this splits open again, I'll go the MOCAL/Aeroquip route...   | ||

| Steve Magnusson (91tr)

Intermediate Member Username: 91tr Post Number: 1959 Registered: 1-2001 |

Anyone got a jpeg to post of the oil system for the 328 from the OM? Although you guys are focusing on the mechanical, are the fractures consistent with a fatigue failure from the internal pressure? | ||

| dave handa (Davehanda)

Intermediate Member Username: Davehanda Post Number: 1296 Registered: 5-2001 |

I was going to say the same thing, can you find any impact damage where anything is hitting it? A bad motor mount may be the cause. Also, were the replacement installed with the rubber bushings? Thinking maybe that w/o the bushings they may get too much vibration and strain. I think you need to look over the installation very carefully and perhaps get a second opinion on the install process. | ||

| Lawrence Coppari (Lawrence)

Member Username: Lawrence Post Number: 713 Registered: 4-2002 |

Based on your description of the problem and that it has now happened twice, I have to wonder whether the problem could be engine movement. A number of years ago my cooler sprang a leak shortly after I revved up the engine before the oil was completely warmed up. The oil filter internals were crushed by the high pressure. Since that time, I don't go over 3K rpms until I see the oil temperature rising. Mine is an '87 328. | ||

| jeremy andrew dixon (Jeremydixon)

New member Username: Jeremydixon Post Number: 1 Registered: 6-2003 |

Euro 328GTB 1988 No 75301 I am having a reoccurring problem of split engine coolers.On three separate occasions the engine oil cooler has failed, twice at track days and once on the driveway at home. The intervals are aproximatly 2 years/4000 miles. A split develops at about 35mm back from the lower pipe union in the bottom tank. After Failure 2,I replaced the 18 row Ferrari origional with a 23 row unit with 3/4 inch BSP fittings and new pipes, I increased the length of the lower pipe by 20mm and the cooler sits about 20mm futher towards the front of the engine bay (because of its larger size). The idea of this modification was to 1. put less strain on the lower fitting and pipe 2.increase oil cooling for track days and 3.reduce the cost of replacement to about 1/4 of OM part.The 23 row unit has now failed in the same way as the others. Backgruond infomation:- Oil presure 75 psi at 5000 rpm aprox 200 deg f synthetic oil 10W50. Can anyone help me solve this frustrating and expensive (potentialy very expensive) problem permanetly. many thanks |