| Author | Message | ||

| Jeff Green (Carguy)

Member Username: Carguy Post Number: 418 Registered: 10-2002 |

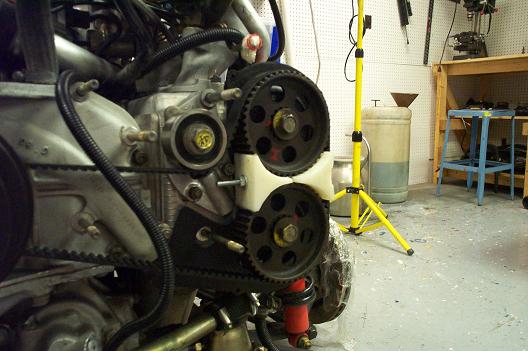

Hi Henryk...on my wedges, the surfaces that contacts the cam pulleys are just kinda "scuffy" and not grooved. I thought about grooves, but also figured if I had to move one cam just slightly and grooves wouldn't allow it. I'm surprised at how little tightening is needed to fix the cams in place. As for room for wrenches behind the cam pulleys, there is plenty of room on the passenger's side, but the driver's side is tight with barely more than 3/16 inch of space. The portion of the cam shafts behind the pulleys does not have any flats, but just a shallow groove that goes about 3/4 way around the shaft itself. Not very good for using a wrench. Vice Grips would work however. I'm sure that pieces of wood would work just as good for making wedges, I just wanted to be a little bit fancy. | ||

| Henryk (Henryk)

Intermediate Member Username: Henryk Post Number: 1024 Registered: 8-2001 |

Jeff: Nice work.....are the pieces grooved?....do you think that two pieces of wood, shaped like you have would work? Isn't there a place behind the cam sprocket to place a wrench? | ||

| Verell Boaen (Verell)

Intermediate Member Username: Verell Post Number: 1025 Registered: 5-2001 |

Looks like it will work. An alternative I've described before is to use 1 of these pieces, & replace the other one with a strip of 1/4" thick, 1" wide steel or AL just about 1" longer than the gear-gear centerline w/ a strip of belt flattened on it. This won't let the gears rotate, and also ensures the gears relative alignment. BTW, those cam gears look like the ones on a Dodge Stealth/Mitsu. 3K. The dodge cam lock-down method is to put a flat plate behind the 2 pulleys with bolt-holes thru it. Put a bolt w/large washer thru a hole in each cam gear's webbing & tighten up against the plate. The back of the webbing on the Stealth/3K was flat against the rear edge of the gear tho. If your web is recessed, then may need to use washers to fill in the gap. | ||

| Paul Jeffery (Peajay)

Junior Member Username: Peajay Post Number: 105 Registered: 4-2002 |

Yes I have had the same thought about my next belt change, this looks like a pretty good method to me, especially if you use some matchmarks as well to catch any possibilty of movement. | ||

| Jeff Green (Carguy)

Member Username: Carguy Post Number: 416 Registered: 10-2002 |

Many already know I've pulled the motor out of my TR for a Cambelt and Tensioner Bearing change. This was due to an oil leak out of the front Cranshaft Seal. All else is good. Since I just need to change belts & bearings, it would be nice not to have to remove the cam covers, along with all the associated hardware, to lock down the cams using the "folded paper" method. To save time and most importantly - money - I reviewed the archives for lock-down methods. There were several good ideas, but I thought I'd try one on my own. I used nylon block stock, cut, ground and shaped to fit the cam pulleys. I drilled a hole through both pieces, and used threaded rod compress them together. It doesn't take much tension to lock the cams down, so caution would be recommended not to over tighten the wedges. I made a set for each side of the motor. What do you guys think....is this method okay? Do you think it causes "bad" stresses on the cams? Thank You for your input.    |