| Author | Message | ||

| Stewart Chung (Navygakman)

Junior Member Username: Navygakman Post Number: 106 Registered: 2-2002 |

Matt Morgan (aka Kermit) has done a number of mods for my car (Electromotive system included) and he stood behind his work above and beyond that expected from a vendor. I have no hesitation recommending him for any products or services he has to offer. As much as Paul feels that it is his duty as a Chatter to warn us of his bad experience, I feel that it is mine to state my good experience. I am with you Jeff. | ||

| Paul Sloan (Sloan83qv)

Member Username: Sloan83qv Post Number: 622 Registered: 3-2001 |

Since I have no experience with Mr. Davidson I will not comment on his statements. I will continue to warn everyone when Matt Morgan tries to sell his wares on Ferrari Chat as all should be aware of his actions. If one chooses to do business with Mr. Morgan than they do so after being warned and so be it. Again I would expect any other Chatter to warn me of such a vendor. Paul Sloan | ||

| Ted Gage (Tedmac)

New member Username: Tedmac Post Number: 30 Registered: 2-2003 |

Thanks for all the input. When I began this adventure, The first call I made was Nick's. What I hoped to hear was "Yes, we've done a number of those, send us your damper, trigger wheel, sensor, and $$$'s, and we'll send you a bolt-on that works fine". What I got instead was "We can figure something out. Call us when you're ready". Click. Now maybe I was talking the janitor or the UPS delivery guy, but I wasn't really interested in paying someone to "figure something out". Hence the design. Mounting behind the plane of the belts looks like a good idea, I'll take a look at it. | ||

| Jeffrey Davison (Jeffdavison)

Junior Member Username: Jeffdavison Post Number: 185 Registered: 7-2002 |

I will have to strongly disagree with Mr. Slaon about sending Durable 1 money in exchange for product. "Kermit" was friendly, very accomadating with pictures and answers to my questions. I purchase the trigger wheel, sensor mount, a shift linkage adjustment kit. He also included some wheel mounting tools gratis. Prices were exceptionally reasonable and the shipping was very fast and very well packaged, and the quality of the machine work was top notch. Based on this experience I have no trepidations dealing with Durable 1 and would recommend dealing with them, dispite Mr. Sloans warnings, both public and private, to the contrary. For some reason I can't post pictures here, but if anyone would like pictures of the part, just email me directly. Again Mr. Slaon is hijacking a thread, based not on the merits of a technical issue, where he once said he would not, but based on a personal issue unrelated directly to the topic. Based on my experience with both people, only one has been credible. Jeff Davison | ||

| Paul Sloan (Sloan83qv)

Member Username: Sloan83qv Post Number: 621 Registered: 3-2001 |

Nicks Forza Ferrari who has been a sponsor of Ferrari Chat was the developer of the system I use and is shown in the photo that CC posted (my car). I would not advise anyone sending any money to durable one (Matt Morgan)as I will be glad to post photo's of the holes he put in my QV Head after being paid in full. The photo's were taken by Mr. Morgan. After a year (a lawyer and the local sheriff)I finally got my damaged heads out of his shop and they are now being repaired at a FIRST RATE shop and yes Mr. Morgan kept the $5000 I paid him in advance. I think the system developed by Ted has a great pickup mount and give him credit for that setup. | ||

| C.C.ofAtlanta (Atlantaman)

Member Username: Atlantaman Post Number: 252 Registered: 3-2002 |

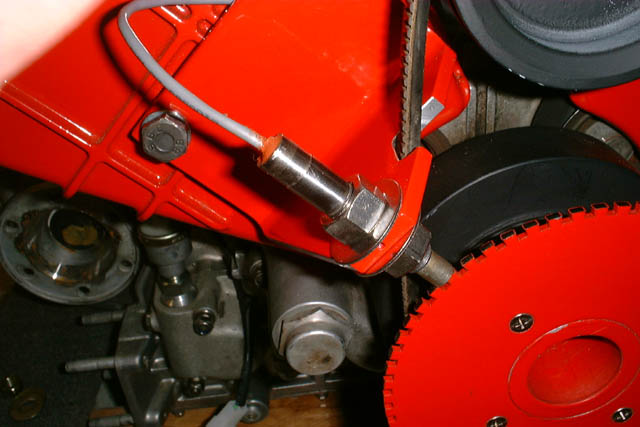

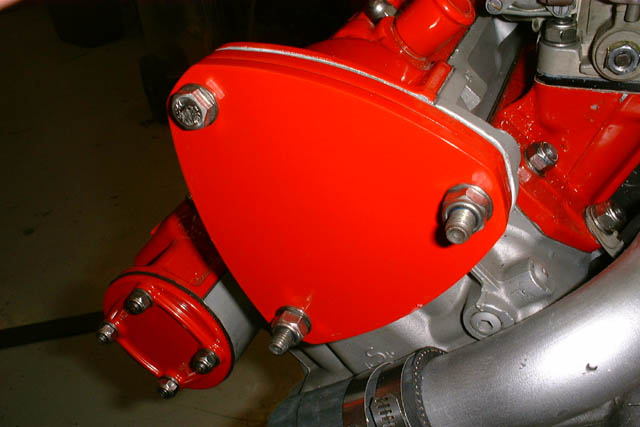

I know that the trigger wheel is from Electromotive--the yellow car is mine.... I just installed a complete TEC-3 system. The point of showing the pictures is to show alternative mounting methods for the timing wheel. (the mounting like the red one is crazy, occasionally waterpump belts break and in the red pictures you can not get a belt on without removing the wheel) If you examine mine you will see that I CNC milled out the center of the wheel and then CNC drilled and tapped 5 holes to screw it to the dampener. GUARANTEED to never slip or move. | ||

| Matt Morgan (Kermit)

Junior Member Username: Kermit Post Number: 145 Registered: 8-2001 |

CC, the Trigger Wheel that you are showing is another of the designs that are part of this Corporation's product line. We have on file a letter of recognition from Electtromotive recognizing that. This is the same one previously offered on NFF's site, and is now on an introductory special on the new site. It is very easy to mount, simple set screws retain it. A true bolt on.I checked a minute ago, and while it isn't thru the "Bug", we are transfering to a new provider, so it should be up soon. Please be patient. Thanks | ||

| billy bob (Fatbillybob)

Member Username: Fatbillybob Post Number: 315 Registered: 8-2002 |

atlantaman, Is that a stock timing wheel from electromotove to fit the back of the 308 damper? How is it mounted on? | ||

| Philip Airey (Pma1010)

Member Username: Pma1010 Post Number: 364 Registered: 7-2002 |

I have an HPX. Bought through Nick a year and a half ago. Operates flawlessly. Looks like the 8.34 pm pic posted by Atlantaman. | ||

| C.C.ofAtlanta (Atlantaman)

Member Username: Atlantaman Post Number: 251 Registered: 3-2002 |

2  | ||

| C.C.ofAtlanta (Atlantaman)

Junior Member Username: Atlantaman Post Number: 250 Registered: 3-2002 |

here are a few pics that i pulled up  | ||

| C.C.ofAtlanta (Atlantaman)

Junior Member Username: Atlantaman Post Number: 249 Registered: 3-2002 |

Mike--the HPV IS an Electromotive system! lots of us have done this before and I have to say that I would NOT go with a timing sproket mounted on the outside like this. Look thru the archives--there are better looking kits that have been posted. | ||

| David Feinberg (Fastradio2)

Member Username: Fastradio2 Post Number: 273 Registered: 4-2002 |

So Ted... Looks great! But, how about a setup for my BB? David | ||

| Ted Gage (Tedmac)

New member Username: Tedmac Post Number: 29 Registered: 2-2003 |

After reviewing the Electromotive documentation, it appears that the trigger wheel and sensor are identical for the Tech II and Tech III systems. This means that this kit will probably work for both Tech II and Tech III electronics. This kit is crank mounted and meets all Electromotive recommendations for installation. This kit installs in a couple of hours or less. You have to install the Damper/pulley, bolt on the Trigger wheel mounting cup and sensor bracket, adjust the trigger wheel to the proper tooth, and set the gap. Remove the distributors, attach the cover plates and you�re finished with trigger wheel installation. I�m posting a couple of pictures of the prototype. There are two differences between the design pictured and the bolt-on version. In the prototype the trigger wheels were matched drilled, as the timing was spot on. For the bolt-on version, the trigger wheel is slotted and can be rotated for adjustment. This results in simple user calibration: turn the wheel to the trailing edge of the 11th tooth and tighten 4 Allen screws. The second difference is the sensor carrier, which can be easily removed and reattached for alternator and A/C belt replacement without the need for recalibration. The Damper/pulley must be sent in, as the cup and pulley are machined and pinned to lock them in synchronization. This amounts to a single hole drilled in the pulley face (no irreversible modifications). Also, the trigger wheel is machined and mounted to the cup. Then the entire assembly is trued. The sensor is mounted in the carrier and the entire assembly checked for perfect alignment. The kit also includes distributor covers that cap off the camshafts. Every part needed is included in the kit with all associated hardware. Standard plating is clear hard anodize which matches the engine aluminum castings and covers. Powder coating is optional.   Bill of Materials: User supplied components 1. 6� Trigger wheel 2. Trigger sensor 3. Damper/pulley Trigger wheel mounting components 4. 1 each Trigger wheel Mounting Cup 5. 1 each Mounting Cup bolt 6. 1 each Mounting Cup washer 7. 1 each Damper/pulley to Mounting Cup Index pin 8. 4 each Trigger wheel adjustment socket head screws (stainless steel) 9. 4 each Trigger wheel adjustment washers (stainless steel) Sensor components 10. 1 each Sensor mounting bracket 11. 2 each Sensor mounting bracket bolts 12. 2 each Sensor mounting bracket washers (stainless steel) 13. 2 each Sensor mounting bracket spacer 14. 1 each Adjustable sensor carrier 15. 2 each Adjustment carrier bolts (stainless steel) 16. 2 each Adjustment carrier washers (stainless steel) 17. 2 each Set screws (stainless steel) Distributor cover components 18. 2 each Distributor covers 19. 4 each Distributor cover nuts, locking (stainless steel) 20. 2 each Distributor cover bolts (stainless steel) 21. 6 each Distributor cover washers (stainless steel) | ||

| Mike Procopio (Pupz308)

Member Username: Pupz308 Post Number: 486 Registered: 10-2002 |

How does this system relate to Nick Scianna's HPV Electromotive ignition? | ||

| Verell Boaen (Verell)

Intermediate Member Username: Verell Post Number: 1070 Registered: 5-2001 |

BillyBob, Re-read Ted's post more carefully. He's got a crank damper mounted trigger wheel w/the sensor bolted to the timing drive gear cover. | ||

| billy bob (Fatbillybob)

Member Username: Fatbillybob Post Number: 314 Registered: 8-2002 |

Your system as designed may not work to trick the smog police. You can trigger the tec2 with a cam or crank wheel and sensor. It sounds like you went with the cam sensor method. The best way is to make a wheel that goes on the crank damper so the police can't see it. It is harder to hide a cam wheel unless the covers still fit. I am not so sure about doing the timing from the cam either. I think the crank is the source of where everything starts. You can mess up your cam positions and have belt issues that can render the real timing improper. There is just more to go wrong. Also you can mistime the relation of the 5-8 bank to since you have another belt. This all makes for a worky system. The goal to and ecu is to make everything mechanical more simple and change your mechanical problems to easier electrical troubleshooting. So if you time off the cam you stil have more mechanical issues. Others may disagree. Also Tec3 is the new unit that uses a spearate ecu from the dfu's. Thus it is easier to hide the units and camo the dfu's to make things look stock. You see in some states like kalifornia you need to pass the sniffer and the visual inspection. | ||

| Alan Ing (Alan)

New member Username: Alan Post Number: 15 Registered: 2-2002 |

Hi Ted, I would be intrested in your set up, do you have pictures? I have Tec II setup that I have not installed yet and would like more information. | ||

| Richelson (Richelson)

Member Username: Richelson Post Number: 877 Registered: 12-2001 |

I would be interested in one. | ||

| Ted Gage (Tedmac)

New member Username: Tedmac Post Number: 28 Registered: 2-2003 |

We�ve just completed an Electromotive Tech II bolt-on kit for a 79 308 GTB. All the parts are captured and produced on NCM (numerical control machine) equipment. The kit uses a cup that bolts inside the front pulley and holds the trigger wheel. The trigger wheel is machined so that it can be adjusted to Electromotive specifications. A bracket attached to the lower two bolts of the timing gear cover of cylinders 1-4 holds the trigger sensor. All bolts, spacers, washers, and hardware are documented and can be provided. The kit also includes covers for removed distributors. I was wondering if there is any interest in this kit by 308 owners who would like to upgrade to an Electromotive system? The kit is a true bolt-on. No user machining is required. The pulley, trigger wheel, and sensor must be provided for fitting. If interested, please respond to this post or email the author. |